1.Guillotine shearing machine cuts metal sheet vertically, the movement is smooth, the structure is rigid, and it effectively reduces vibration and deformation.

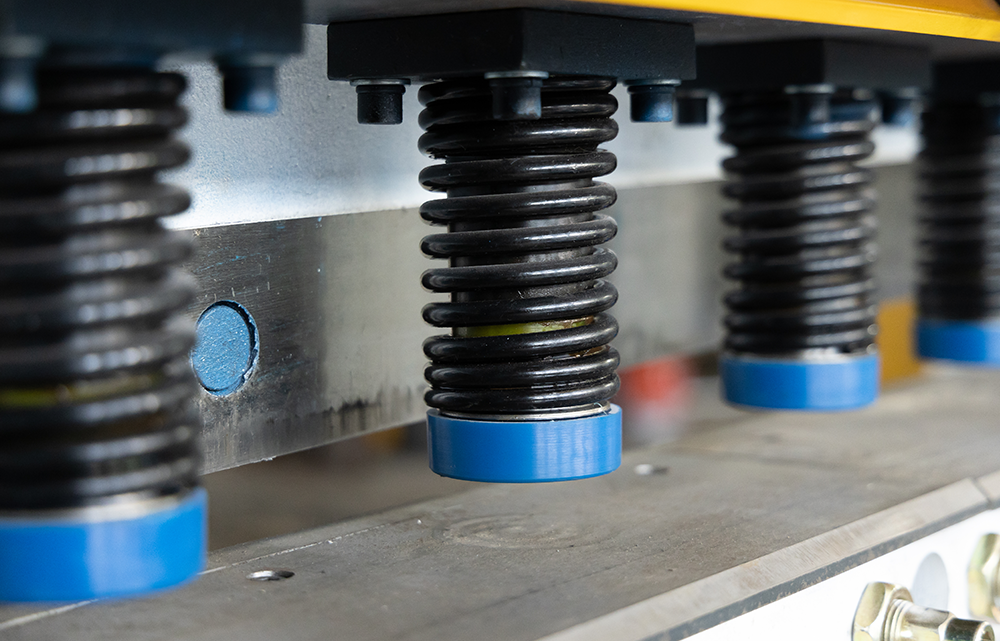

2.During the shearing process, the contact angle between the blade and the board dynamically changes, gradually decreasing from large to small, resulting in a more uniform distribution of shear force and reducing machine impact.

3.The CNC hydraulic shearing machine features a safety guard with electrical interlocking, meeting CE standards and guaranteeing safe operation of the hydraulic metal shear.

4.A guillotine shearing machine with semi-automatic feeding system minimizes loading and unloading wait times, reducing overall processing duration. Operators avoid entering the cutting area to push material, instead working safely outside the protective zone, significantly lowering the risk of workplace injuries.

Model |

Cutting thickness (mm) |

Cutting length (mm) |

Cutting Angel (°) |

Stopper Adjust Range |

Stroke time (min-1) |

Motor (KW) |

Dimension |

Weight |

QC11Y-6X2500 |

6 |

2500 |

0.5~1.5 |

500 |

20 |

7.5 |

2850X1800X1950 |

4 |

QC11Y-6X3200 |

6 |

3200 |

0.5~1.5 |

500 |

16 |

7.5 |

3450X1850X2000 |

5.2 |

QC11Y-6X4000 |

6 |

4000 |

0.5~1.5 |

500 |

12 |

7.5 |

4550X1850X2000 |

7 |

QC11Y-6X6000 |

6 |

6000 |

0.5~1.5 |

500 |

10 |

15 |

6940X2200X2450 |

11.5 |

QC11Y-8X2500 |

8 |

2500 |

0.5~1.5 |

500 |

18 |

11 |

2860X1850X2150 |

5 |

QC11Y-8X3200 |

8 |

3200 |

0.5~1.5 |

500 |

14 |

11 |

3460X1850X2150 |

6.2 |

QC11Y-8X4000 |

8 |

4000 |

0.5~2 |

500 |

12 |

11 |

4550X1750X1950 |

8 |

QC11Y-8X6000 |

8 |

6000 |

0.5~2 |

500 |

10 |

15 |

6940X2250X2550 |

14 |

QC11Y-10X2500 |

10 |

2500 |

0.5~2 |

500 |

15 |

15 |

2950X1850X2050 |

7 |

QC11Y-10X3200 |

10 |

3200 |

0.5~2 |

500 |

13 |

15 |

3650X1850X2050 |

8.3 |

QC11Y-10X4000 |

10 |

4000 |

0.5~2 |

500 |

12 |

18.5 |

4550X2050X2150 |

9 |

QC11Y-10X6000 |

10 |

6000 |

0.5~2 |

600 |

10 |

18.5 |

6850X2550X2650 |

17 |

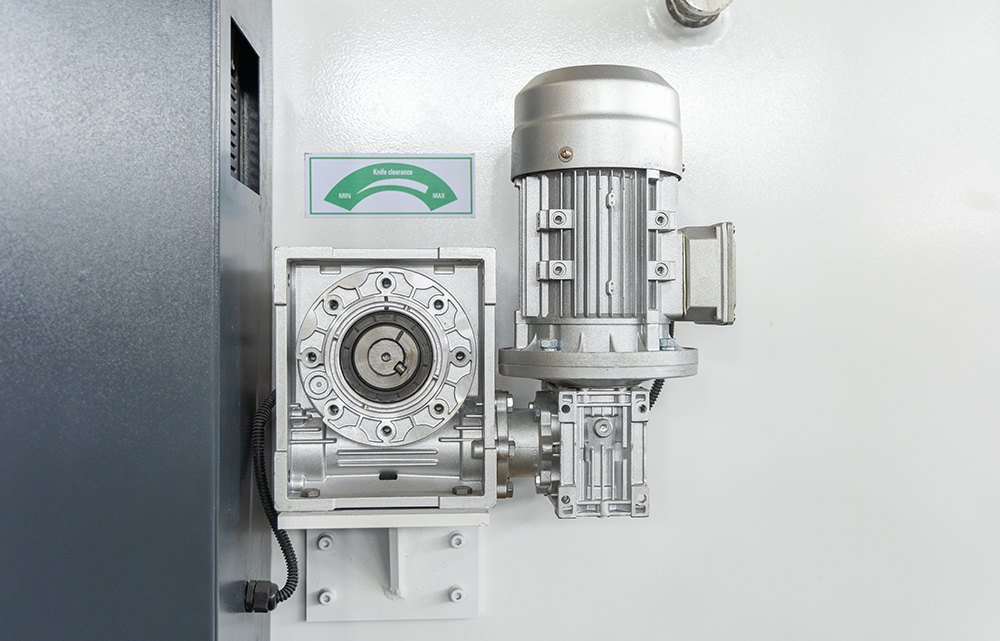

It features a large 7" color LCD touch screen, the machine offers automatic blade clearance and rake angle adjustment, along with unlimited user programs and step storage for enhanced productivity and ease of use.

The automated feeding process is fast and stable, reducing waiting time for loading and unloading, shortening processing time. Workers don’t need to enter the cutting danger zone to push materials, and always operate outside the safety protection range to reduce the risk of work-related accidents.