Understanding Press Brake Efficiency and Key Performance Metrics

Defining Press Brake Efficiency: Cycle Time, Throughput, and Machine Availability

Press brake efficiency is driven by three core metrics:

- Cycle Time: The total time to complete one bending cycle, from material loading to unloading. Reducing cycle time by 15–20% can increase annual output by 180–240 hours (Precision Metalforming Association [PMA], 2023).

- Throughput: The number of parts produced per hour. A 20% improvement often results from optimized tool paths and reduced idle periods.

- Machine Availability: Uptime percentage excluding planned maintenance. Top-tier workshops achieve 85–90% availability by proactively addressing hydraulic leaks and misalignments.

How to Track KPIs Like Setup Time, Changeover Time, and Downtime Effectively

| Tracking Method | Setup Time Reduction | Downtime Accuracy |

|---|---|---|

| Manual Logbooks | 5–10% | ±25% |

| IoT Sensors + OEE Software | 25–35% | ±3% |

| Automating data collection with OEE (Overall Equipment Effectiveness) software reduces changeover time by 30–50%. Real-time dashboards identify bottlenecks such as frequent tool changes. For example, shops using automated tracking report a 43% faster response to unplanned downtime (SME, 2023). |

The Role of Data-Driven Decision-Making in Measuring Operational Success

Data analytics turns raw performance metrics into actionable strategies:

- Real-time cycle time monitoring cuts variation by 18–22% through adaptive toolpath corrections.

- Machine learning predicts hydraulic component failures 72 hours in advance, reducing unscheduled downtime by 55% (ASQ, 2024). Workshops with ERP-integrated press brake systems achieve 12–15% higher annual output by aligning throughput data with material waste and workforce scheduling.

Leveraging CNC Technology and Automation for Smarter Press Brake Operations

How digital controls enhance press brake precision and repeatability

Modern CNC (Computer Numerical Control) systems allow programming of bending sequences within tolerances under ±0.1°, reducing manual adjustments by 70% compared to manual presses. Digital storage of tooling parameters and bend angles ensures consistency across runs. Manufacturers adopting CNC-guided backgauges and angle correction systems report a 45% reduction in scrap rates.

Integrating CNC systems for real-time monitoring and error reduction

The DA-66T interface gives operators instant information about tonnage levels and machine alignment, which helps catch potential problems early on before anything actually goes wrong. The system has built-in sensors that keep track of where the ram is positioned and what's happening with the hydraulic pressure throughout the process. This monitoring capability alone cuts down on those frustrating unexpected shutdowns by around 30% each year according to industry reports. Another great feature lets workers run through bending operations in three dimensions first. They can spot any possible collisions between parts in this virtual space instead of discovering them during actual production runs. Some manufacturers have reported seeing roughly a quarter fewer setup mistakes when using these simulations, especially helpful for facilities dealing with lots of different product variations.

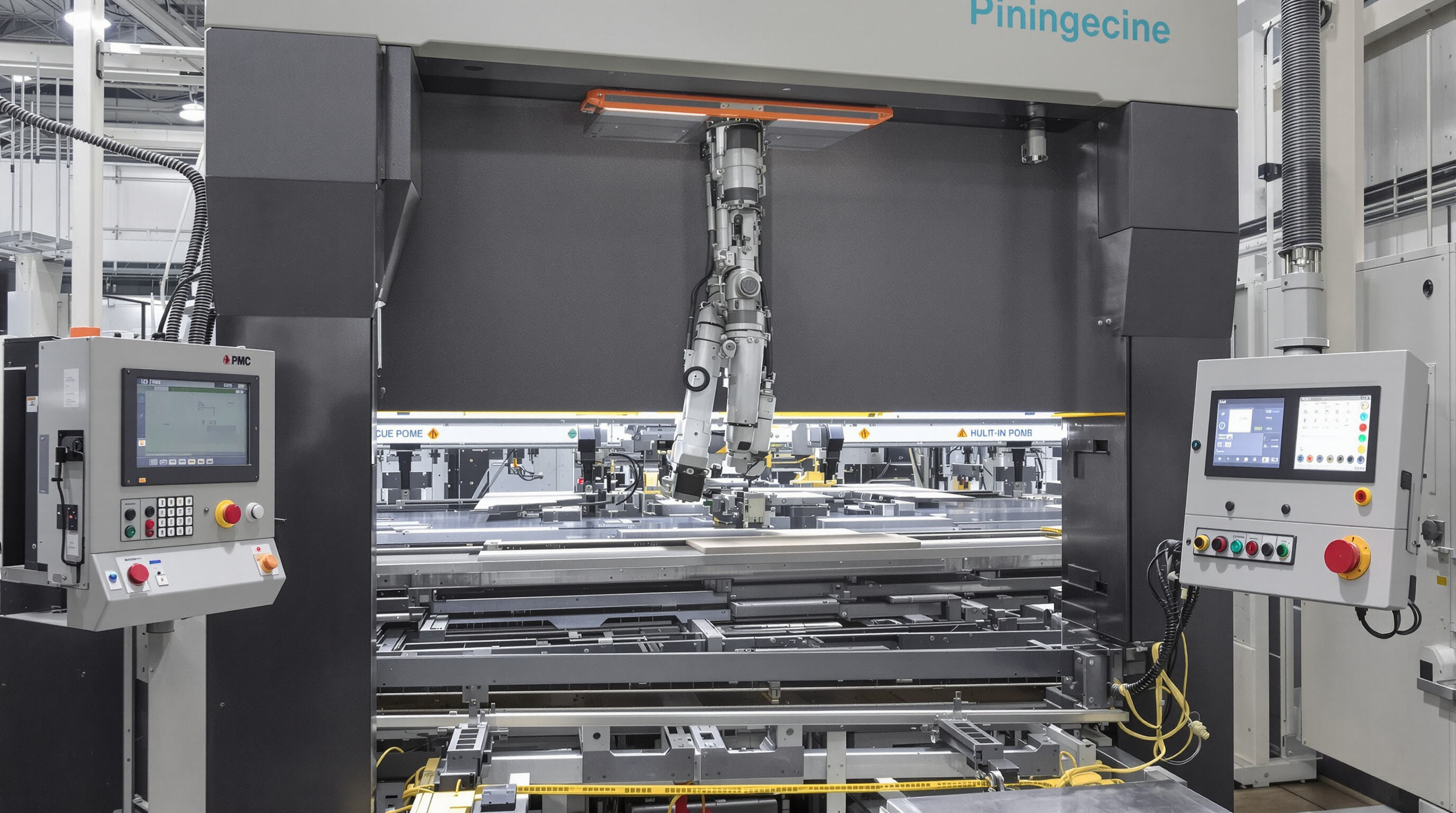

Automation trends: from semi-automatic setups to full robotic bending cells

Tool changes on semi automatic machines can happen in less than 90 seconds these days, and robotic bending cells handle all sorts of tasks from loading materials to flipping parts around and then unloading them when done. According to some recent industry data from last year, shops that have integrated robotic arms into their press brake operations report about a 22 percent improvement in cycle times plus roughly 18% better tool usage rates. The fully automated production lines equipped with pallet changers and those fancy vision guided robots are becoming pretty economical even for smaller runs. We're talking about batches as tiny as fifty pieces being viable now which was unheard of just a few years back.

Case study: increasing throughput by 40% using automated material handling

A Midwest fabricator upgraded its press brake with robotic handlers and automated die storage, minimizing manual intervention during 12-hour shifts. By synchronizing robot speed with machine cycle times, the system achieved 320 bends/hour—a 40% gain in throughput—while maintaining 99.6% angular accuracy on 3mm stainless steel components.

Optimizing Bending Sequences and Tooling Setup for Minimal Cycle Time

Strategies to minimize repositioning and tool changes during production

Getting efficient bending sequences right starts by cutting down on all that wasted time when machines aren't actually working. The trick is multi-stack tooling which lets operators do several bends in one go without swapping dies around. Fabrication Insights reported somewhere between 15 to 20 percent savings in cycle times for shops dealing with lots of different jobs. When programming these sequences, grouping together similar angles or radii makes sense because it cuts back on how many times the machine has to rotate and move materials around. And for those really complicated parts? Start with operations that use common tools first. This approach gives the whole process a solid foundation before moving onto the more delicate bends that follow.

Using simulation software to visualize and refine bending sequences

3D simulation tools eliminate trial-and-error programming by predicting deformation and detecting collisions before production. These platforms analyze sequences for geometric conflicts, suggesting optimizations that cut handling time by 30% in sheet metal applications. Top-tier systems integrate directly with CNC controls, translating simulated sequences into machine instructions while ensuring ±0.1° angle consistency.

Best practices for press brake tooling selection based on material and geometry

Tooling choices significantly impact cycle efficiency:

| Factor | Thin-Gauge Steel | Thick Aluminum | Stainless Steel |

|---|---|---|---|

| Optimal V-die width | 6–8x material thickness | 8–12x thickness | 5–7x thickness |

| Punch radius | 1–3x thickness | 3–5x thickness | 1–2x thickness |

| Tool material | Tool steel | Carbide inserts | Tungsten carbide |

Matching punch profiles to target radii and selecting appropriate die openings minimizes springback compensation. Modular tool systems with standardized heights support rapid adaptation across mixed-material jobs.

Implementing quick-change tooling to slash setup time and changeover time

Magnetic clamping and RFID-enabled toolholders reduce die setup time from hours to minutes. One automotive supplier reduced tool changeovers by 89% using quick-change systems with automatic geometry recognition—saving 217 production hours annually. Pairing these systems with pre-staged tool carts maintains continuous workflow between jobs.

Maximizing Productivity with Advanced Delem Controllers (DA-53T, DA-66S, DA-66T, DA-69T)

How to Leverage Delem DA-66S for Operational Success and Precision Control

The Delem DA-66S enhances press brake efficiency through real-time angle correction and adaptive sequencing. Capable of interpreting complex drawings with ±0.1° accuracy (FabTech 2023), it reduces material waste by 18% while sustaining consistent throughput. Its dual-mode interface supports smooth transitions between manual adjustments and automation, making it ideal for high-mix production.

Achieving Precision with Delem DA-66S Product Drawing Interpretation

Integrated DXF file processing automatically maps bend lines and calculates springback compensation, eliminating manual entry errors and cutting programming time by 35%. The controller’s collision detection previews toolpaths in 3D, preventing costly downtime due to misaligned dies.

Enhancing Operations with Delem DA-66T: Faster Processing and Intuitive Interface

Delem’s DA-66T accelerates production with key features:

| Feature | Benefit | Productivity Gain |

|---|---|---|

| Multi-axis sync | Simultaneous ram and back gauge control | 22% faster cycles |

| Cloud-based storage | Instant program retrieval | 40% setup reduction |

| Tactile feedback | Error prevention during manual override | 90% fewer defects |

Optimizing Production with Delem DA-69T Automatic Mode and Offline Programming

The DA-69T’s offline programming allows uninterrupted production while engineers develop new programs remotely. Field tests show 98% first-pass accuracy on complex geometries when combining its automatic crowning system with hydraulic deflection compensation.

How Does Delem DA-53T Simplify Tool Programming and Reduce Setup Errors?

The DA-53T’s guided tool configuration wizard reduces setup errors by 67% via:

- Automatic die recognition using RFID tagging

- Pressure calculation based on material thickness sensors

- Visual alerts for incompatible punch/die combinations Operators achieve 50% faster changeovers when switching between common tasks like channel forming and hemming.

Operator Training and Maintenance Strategies to Sustain Long-Term Efficiency

Why operator expertise is critical to maximizing press brake efficiency in your workshop?

Skilled operators reduce setup errors by 60% and prevent 30% of unplanned downtime caused by improper alignment or handling (Fabrication Insights 2023). Proficiency in CNC parameter interpretation directly improves bend accuracy, material yield, and rework rates.

Designing training programs around CNC controls, safety, and troubleshooting

Effective training combines:

- CNC controls mastery: Hands-on practice with angle correction and force calibration

- Safety protocols: OSHA-compliant lockout/tagout procedures during die changes

- Troubleshooting drills: Simulated scenarios like crowning deviations

Trained workers achieve 90% faster setup times and 45% fewer safety incidents.

Bridging the skill gap with augmented reality and digital work instructions

AR-guided bending sequences reduce training time for new operators by 70%, maintaining <0.1° angular precision. Embedded digital work instructions in CNC interfaces reduce programming mistakes by:

- Visualizing tool paths before execution

- Alerting operators to mismatched die selections

- Providing real-time tonnage limits based on material grade

Establishing a preventive maintenance schedule for hydraulic and mechanical components

| Maintenance Activity | Frequency | Key Benefit |

|---|---|---|

| Ram alignment checks | 500 cycles | ±0.001" positioning accuracy |

| Hydraulic filtration | 250 hours | 80% reduction in valve failures |

| Frame bolt torqueing | Quarterly | Prevents deflection under load |

Following manufacturer-recommended schedules extends press brake life by 3–5 years and limits annual efficiency loss to less than 2%.

Using sensor data and IoT for predictive maintenance and fault detection

Vibration sensors detect 89% of bearing failures more than 72 hours before failure. IoT-enabled monitors track:

- Oil viscosity changes (±5% from baseline)

- Pump pressure fluctuations (>15% deviation triggers alerts)

- Temperature spikes during high-tonnage operations

This predictive approach lowers maintenance costs by $18k/year per machine through timely, data-driven part replacements.

FAQ Section

What is press brake efficiency?

Press brake efficiency refers to the effectiveness and productivity of a press brake machine, typically measured through cycle time, throughput, and machine availability.

How can I track KPIs for a press brake effectively?

Tracking KPIs like setup time, changeover time, and downtime can be effectively achieved through manual logbooks, IoT sensors, and OEE software for accurate data collection and bottleneck identification.

What advantages does CNC technology bring to press braking?

CNC technology enhances press brake operations by improving precision, enabling real-time monitoring, reducing manual adjustments, and decreasing scrap rates through automated controls.

How can I reduce cycle time in press brake operations?

Cycle time in press brake operations can be reduced by optimizing bending sequences, minimizing repositioning and tool changes, using multi-stack tooling, and employing simulation software for sequence refinement.

What maintenance strategies help sustain long-term press brake efficiency?

To sustain long-term press brake efficiency, establish preventive maintenance schedules for hydraulic and mechanical components, utilize IoT sensors for predictive maintenance, and conduct regular checks for alignment and filtration.

Table of Contents

- Understanding Press Brake Efficiency and Key Performance Metrics

- Leveraging CNC Technology and Automation for Smarter Press Brake Operations

- Optimizing Bending Sequences and Tooling Setup for Minimal Cycle Time

-

Maximizing Productivity with Advanced Delem Controllers (DA-53T, DA-66S, DA-66T, DA-69T)

- How to Leverage Delem DA-66S for Operational Success and Precision Control

- Achieving Precision with Delem DA-66S Product Drawing Interpretation

- Enhancing Operations with Delem DA-66T: Faster Processing and Intuitive Interface

- Optimizing Production with Delem DA-69T Automatic Mode and Offline Programming

- How Does Delem DA-53T Simplify Tool Programming and Reduce Setup Errors?

-

Operator Training and Maintenance Strategies to Sustain Long-Term Efficiency

- Why operator expertise is critical to maximizing press brake efficiency in your workshop?

- Designing training programs around CNC controls, safety, and troubleshooting

- Bridging the skill gap with augmented reality and digital work instructions

- Establishing a preventive maintenance schedule for hydraulic and mechanical components

- Using sensor data and IoT for predictive maintenance and fault detection

- FAQ Section