The Role of Hydraulic Power in Ironworker Shearing Force

The hydraulic system acts like the power source for ironworker machines, turning fluid pressure into actual mechanical strength. Take a standard 15 ton hydraulic cylinder for example it produces around 30 thousand psi of sheer cutting power, enough to cut right through half inch thick steel plates with clean edges every time. What makes this possible? The system relies on carefully controlled valves that maintain even pressure along the entire length of the cutting blade. Unlike those old fashioned crank driven models from decades ago, modern hydraulic systems don't suffer from annoying mechanical backlash during operation, which means smoother cuts and less wear on equipment over time.

How Shearing Force Is Generated in an Ironworker Machine

The shearing process unfolds in three phases:

- Clamping: Hydraulic cylinders secure the material against the machine bed

- Blade engagement: Upper and lower blades converge at a 0.5°–2.5° angle, reducing the required force

- Fracture propagation: Controlled hydraulic pressure fractures the material along the shear line

Optimizing blade gap to 5%–7% of material thickness improves cut quality by 40% and reduces tool wear (Machinery Digest 2023).

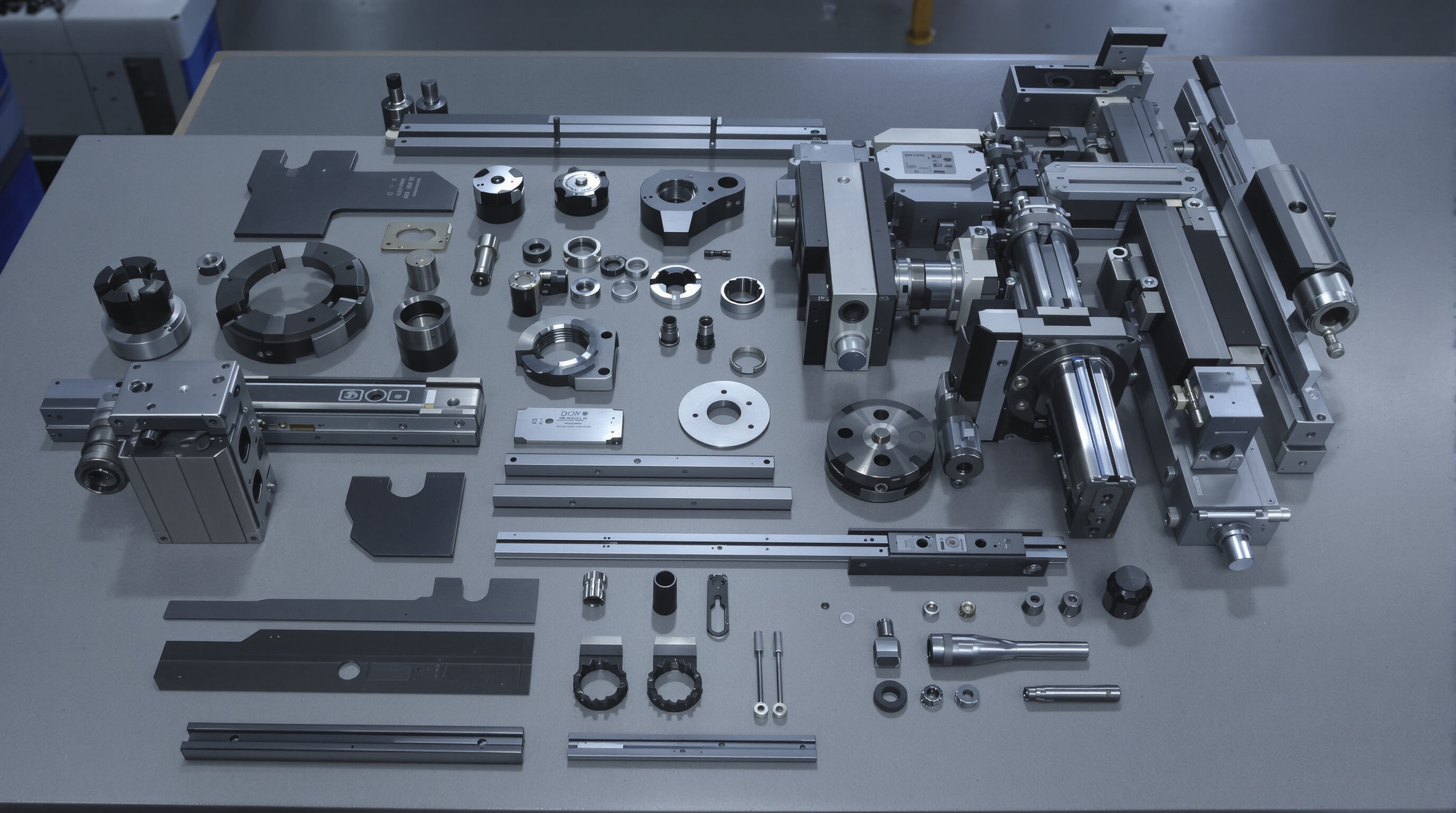

Key Components That Influence Shearing Performance

Critical components directly affect performance and durability:

| Component | Performance Impact |

|---|---|

| Tool-grade blades | Maintain edge integrity under 200+ ton loads |

| Dual-stage hydraulics | Balance speed (100 mm/sec) and force |

| Linear guide systems | Reduce deflection to ®0.001” per foot |

Blade hardness (HRC 58–62) and hydraulic response times under 0.3 seconds are most critical for maintaining consistent shearing force during extended production runs.

Matching Ironworker Capabilities to Shearing, Punching, and Notching Needs

Comparative Analysis of Shearing vs. Punching and Notching Functions

Hydraulic ironworkers handle three main tasks: shearing, punching, and notching. When it comes to shearing, machines apply straight force to slice through metal plates or bars. This operation actually needs around 25 to 40 percent more power compared to punching or notching when dealing with similar thickness materials. Take half inch mild steel as an example. Cutting it takes about 1,200 kilonewtons of shear force, whereas punching the same material only needs roughly 800 kN because the pressure gets concentrated in specific areas. Notching works with much lower forces between 300 and 600 kN, but there's still a need for pretty tight tolerances, usually within plus or minus 0.2 millimeters, to get those clean angled cuts right. These different functions put various kinds of strain on the hydraulic system. Shearing is all about brute strength, punching focuses on being able to repeat the same action consistently, and notching walks a fine line between getting accurate results while working with how flexible different materials can be.

Maximizing Multi-Function Efficiency Without Sacrificing Shear Power

To preserve hydraulic integrity, high-force shearing tasks–such as beam cutting–should be scheduled separately from lighter punching or notching operations. Modern ironworkers allocate 70–85% of system capacity to shearing by default, reserving the remainder for auxiliary functions. Operators can optimize efficiency by:

- Performing high-force shearing before lighter tasks

- Using quick-change tooling to minimize setup time

- Monitoring hydraulic temperature to prevent viscosity loss during prolonged use

Data-Driven Performance Benchmarks for Common Ironworker Models

A 100-ton hydraulic ironworker typically delivers:

- Shearing: Up to 1,100 kN on 25-mm steel plate

- Punching: 22-mm circular holes in structural steel at 60 cycles/minute

- Notching: ±0.15 mm accuracy in 10-mm thick angle iron

Lower-cost 50-ton models exhibit 18–22% reduced efficiency in mixed operations, with hydraulic pressure dropping 15–20% when switching functions. High-end 150-ton units maintain 95% force consistency across operations but require 30% more maintenance. Always verify manufacturer-certified benchmarks against your material specs–mismatched tooling can reduce shear performance by up to 40% in stainless steel applications.

Selecting and Optimizing Tooling for Maximum Shearing Force

Matching Tooling to Material Type and Thickness for Peak Efficiency

Material type significantly affects shearing force requirements. Cutting 10mm stainless steel demands 40% more force than carbon steel of the same thickness (Fabrication Standards Institute 2023). Optimal efficiency is achieved by aligning blade hardness with material tensile strength:

| Material Type | Recommended Tool Hardness (HRC) | Max Thickness Efficiency Threshold |

|---|---|---|

| Mild Steel (A36) | 50–55 | 20mm |

| Tool Steel (D2) | 58–62 | 12mm |

| Titanium Alloys | 62–65 | 6mm |

Advanced Techniques for Adjusting Blade Clearance and Angle

Proper blade clearance minimizes wear and improves cut quality. A 2024 Metal Processing Study found that:

- 8% material thickness clearance reduces burr formation by 73% compared to fixed-clearance tooling

- Dynamic angular adjustment systems reduce required shear force by 18% for 12–20mm plate cuts

Case Study: Doubling Blade Life by Aligning Tooling with Material Specs

A Midwest fabrication plant increased blade life by 110% by implementing three protocols:

- Transitioning from universal to material-specific tool coatings

- Using precision-ground clearance shims (0.01mm tolerance)

- Installing real-time blade temperature sensors

This $84k investment reduced annual tool replacement costs by $217k (Metal Fabrication Quarterly 2024).

Common Tooling Mistakes That Reduce Shearing Force

Dull blades increase required shear force by 30% (PMA 2023 Report), while improper clearance causes:

- 42% higher hydraulic strain when processing aluminum sheet

- 57% more material slippage in stainless steel operations

Operators should verify blade alignment every 500 cycles and maintain hardness tolerances within ±1.5 HRC.

Enhancing Ironworker Performance Through Hydraulic and System Optimization

Fine-Tuning Hydraulic Pressure for Optimal Shearing Performance

Getting the pressure right matters a lot when it comes to keeping things running smoothly. When hydraulic pressure stays within the range of around 2,800 to 3,200 PSI, we see about a 10 to 15 percent improvement in how consistently the shear force works. If the pressure goes outside plus or minus 150 PSI from that sweet spot, the cuts start getting all over the place according to what Industrial Hydraulic Review found back in 2023. These days, most systems have smart controllers that automatically tweak the pressure depending on how thick the material being cut actually is. This automation helps cut down on blade wear by roughly 30 percent compared to when operators set everything manually. Regular maintenance remains important too, though specific practices would depend on the equipment in question.

- Weekly pressure gauge calibration

- Quarterly hydraulic fluid viscosity testing

- Real-time monitoring via integrated pressure sensors

The Impact of Machine Quality and Design on Shearing Consistency

The stiffness of the frame really matters when it comes to how accurate cuts turn out. Machines built with steel frames that are about 20mm thick generally stay within a tolerance range of plus or minus 0.25mm even when working at maximum capacity. But if the frame is only 12mm thick, we start seeing deviations as high as 1.2mm according to research published in Metal Fabrication Tech Journal last year. Another thing that makes a big difference is the design of the blades themselves. When manufacturers incorporate dual shear blade setups, they actually spread out the cutting forces better across the machine. This allows operators to work with materials that are 25% thicker than what would normally be possible without putting extra strain on the hydraulic components.

Strategy: Implementing Load Monitoring to Prevent Force Degradation

Load monitoring systems reduce hydraulic component stress by 40% through predictive analytics. A 2023 case study showed that torque sensors on pump shafts decreased unplanned downtime by 55% while sustaining 98% shear force consistency over 8-hour shifts.

Trend Analysis: Smart Sensors and Automation in Modern Ironworkers

Eighty percent of new hydraulic ironworkers now include IoT-enabled sensors for real-time performance tracking. These systems predict blade replacement needs with 92% accuracy by analyzing vibration and pressure patterns (Automated Manufacturing Report 2024), reducing material waste by 18% through adaptive parameter adjustments during complex workflows.

Maintaining Peak Shearing Force with Proactive Maintenance and Troubleshooting

Routine Maintenance Practices That Preserve Hydraulic Efficiency

Consistent lubrication and fluid management account for 42% of shearing force stability (2024 Hydraulic Systems Report). Weekly checks should include:

- Blade wear assessment using manufacturer-recommended clearance gauges

- Hydraulic pressure verification within ±3% of OEM specifications

- Ram alignment inspection to prevent off-axis stress

Facilities with structured maintenance schedules experience 57% less unplanned downtime than those using reactive approaches.

Troubleshooting Common Issues That Impair Shearing Performance

Uneven deformation or excessive burring often indicates blade wear exceeding 0.15mm clearance. For hydraulic issues:

- Confirm pump output matches load demands

- Check valve block contamination using ISO 4406 cleanliness standards

- Test accumulator pre-charge pressure quarterly

Field data shows 83% of hydraulic force loss stems from particulate contamination rather than mechanical failure.

Controversy Analysis: Reactive vs. Predictive Maintenance in Industrial Settings

While 62% of shops still use run-to-failure strategies, predictive maintenance using vibration analysis and thermal imaging reduces annual blade replacement costs by 34%. Critics cite barriers including:

- $18k–$25k initial investment in sensors

- 140–200 hours of technician retraining

Supporters argue that smart monitoring prevents $740k in annual productivity losses per machine (Ponemon 2023), delivering ROI within 18 months for high-volume operations.

FAQs (Frequently Asked Questions)

How does a hydraulic ironworker machine generate shearing force?

Shearing force in a hydraulic ironworker machine is generated through a hydraulic system that converts fluid pressure into mechanical power. The process involves clamping the material, engaging the blades at an optimal angle, and propagating fractures along the shear line.

What are the key components that influence shearing performance in ironworker machines?

Key components include tool-grade blades for edge integrity, dual-stage hydraulics for speed and force balance, and linear guide systems to minimize deflection during operation. Proper maintenance of these components enhances shearing performance.

How can maintenance and troubleshooting improve the performance of hydraulic ironworker machines?

Routine maintenance such as blade wear assessment and hydraulic pressure verification preserves efficiency. Troubleshooting involves checking pump output, valve block cleanliness, and accumulator pressure to address common shearing issues.

Table of Contents

- The Role of Hydraulic Power in Ironworker Shearing Force

- How Shearing Force Is Generated in an Ironworker Machine

- Key Components That Influence Shearing Performance

- Matching Ironworker Capabilities to Shearing, Punching, and Notching Needs

- Selecting and Optimizing Tooling for Maximum Shearing Force

- Enhancing Ironworker Performance Through Hydraulic and System Optimization

- Maintaining Peak Shearing Force with Proactive Maintenance and Troubleshooting

- FAQs (Frequently Asked Questions)