From CO2 to Fiber: A Technological Shift in Laser Cutting

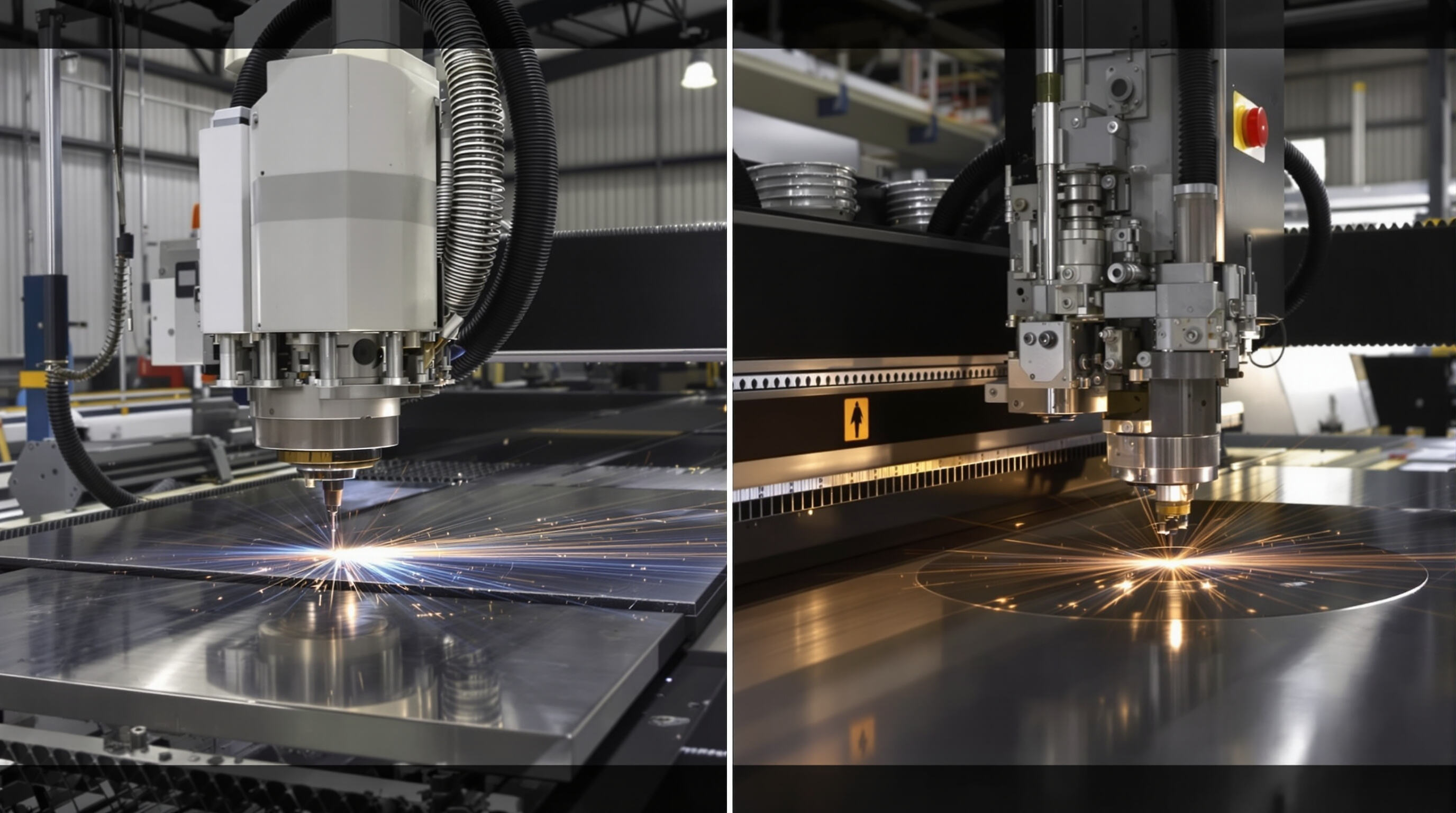

Moving away from CO2 lasers toward fiber laser cutting has been a game changer for manufacturing efficiency. Traditional CO2 setups needed all sorts of gas mixtures plus complicated optical components, while modern fiber lasers work differently. They use these special doped fiber strands to boost the light signal, which cuts down on wasted energy by around 70%, according to last year's Laser Systems Report. The industry saw this change really take off starting back in the early 2010s. What does this mean practically? Well, parts cut with fiber lasers have about 25% narrower edges than before, and these machines tend to last twice as long as older models did. For shops running multiple shifts a day, those numbers translate into real savings over time.

How Fiber Laser Cutting Machines Redefine Precision and Efficiency

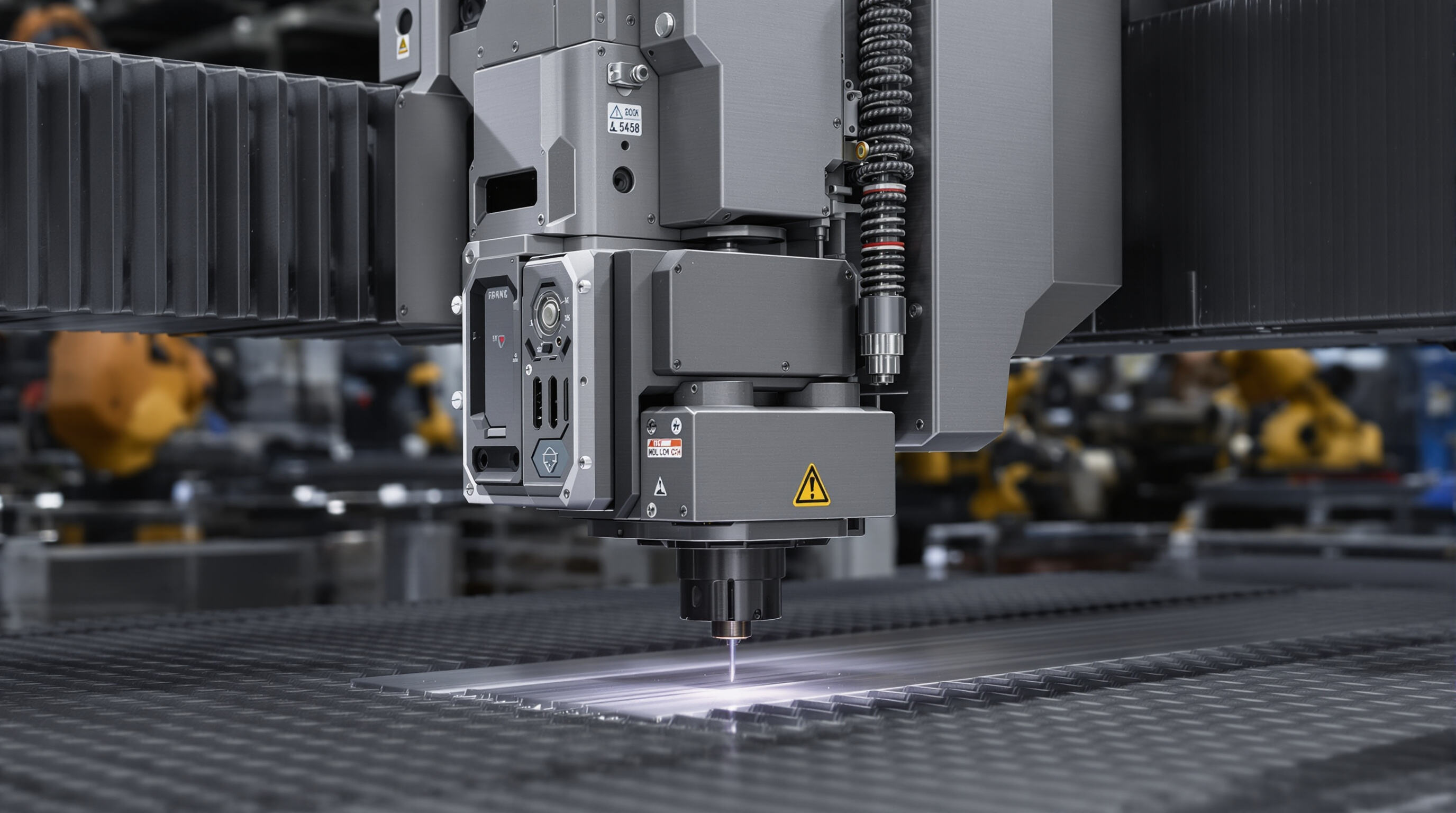

Fiber lasers today can hit positions accurate to about 0.01mm, making those really tiny cuts that mechanical tools just cant do. These lasers have this solid state build that means no more alignment issues which plague CO2 lasers so much. Plus their beams pack an intensity over 1 gigawatt per square centimeter, cutting down on processing time dramatically. Looking at industry standards, fiber laser systems manage to slice through stainless steel three times quicker than plasma torches, plus they create roughly 30 percent less heat distortion according to last year's industrial cutting report from 2024.

Key Innovations Driving Fiber Laser Technology Forward

Three breakthroughs propel fiber laser dominance:

- Beam quality enhancements: New photonic crystal fibers produce near-perfect Gaussian beams, reducing taper in 20mm thick aluminum by 40%

- Modular power scaling: Multi-kW fiber lasers now maintain beam coherence at 15kW, cutting 50mm carbon steel at 1.2m/min

- Predictive maintenance AI: Vibration sensors and thermal imaging prevent 92% of unplanned downtime (2024 Manufacturing Reliability Study)

These advancements position fiber lasers as the backbone of Industry 4.0 manufacturing chains, combining atomic-scale precision with industrial-grade durability.

Unmatched Precision: What Sets Fiber Lasers Apart in Fine Cutting

Understanding Laser Cutter Accuracy and Performance Metrics

The beam focus diameter of fiber laser cutting machines can get down to around 15 microns, which is roughly one fifth the width of a single strand of human hair. What does this mean practically? Positional repeatability hits about plus or minus 5 microns (that's 0.005 mm), which represents something like triple the accuracy compared to older CO2 systems when working with metals. Looking at actual performance numbers, manufacturers track things like kerf width consistency staying within 0.01 mm range and edges remaining pretty much perfectly straight with less than half a degree deviation. These specs translate to consistent quality even after thousands of production cycles. Tests conducted recently demonstrated that fiber lasers keep their precision within 0.1 mm tolerance when cutting through 20 mm thick stainless steel plates. For industries where precision matters most, like medical device fabrication, this kind of reliability makes all the difference between acceptable products and costly rejects.

Micro-Level Control in High-Precision Laser Cutting

Modern fiber laser setups now integrate adaptive optical technology along with high speed sensors that sample at 500 Hz rates to fix those pesky beam distortions as they happen. What does this mean practically? Well, it lets operators tweak the focus point on the fly while making complicated cuts. This real time correction has been shown to cut down thermal warping issues by around two thirds in aluminum microchannel heat exchanger applications. Some recent research from the aerospace sector back in 2024 put numbers to this claim too. They achieved an impressive 0.05 mm precision level when working with thin 0.3 mm titanium foils used in fuel injection parts. That beats what mechanical punching can typically manage which usually falls within a tolerance range of plus or minus 0.15 mm.

Minimizing Tolerance Errors in Precision and Cutting Quality in Laser Machining

Pulse modulation at nanosecond intervals enables fiber lasers to maintain <0.8 mm/m linear thermal expansion variance in 3-meter copper busbars. By integrating AI-powered gas assist control, manufacturers achieve:

| Parameter | Fiber Laser Performance | Traditional Plasma Result |

|---|---|---|

| Edge roughness (Ra) | ±1.6 µm | ≥3.2 µm |

| Angular consistency | ±0.2° | ±1.5° |

| Burr-free cut rate | 99.8% | 82.3% |

Case Study: Achieving Sub-0.1mm Accuracy in Aerospace Components

One major aerospace manufacturer saw their wing spar rework drop by around 40 percent when they made the switch to fiber laser cutting for those tough 7075 aluminum parts. Their new system operates at 20 kW in pulsed mode, capable of slicing through 8 mm thick plates with remarkable precision - just 0.08 mm positional error. The surface finish comes out at about 12 microns, which actually meets the strict AS9100D standards used throughout the industry, so there's no need for any additional machining work afterward. What really stands out though is how much time they saved. Manual deburring used to take workers three whole hours on each unit, but now that process is completely gone. When we do the math, that adds up to roughly $18k savings per aircraft frame built.

Speed, Efficiency, and Material Capabilities of Fiber Laser Cutting Machines

Fiber laser cutting machines deliver transformative performance in industrial manufacturing, combining rapid processing speeds with exceptional material versatility. By leveraging focused light beams and advanced optics, these systems achieve precision cuts while optimizing production workflows across industries.

Increased Cutting Speed and Reduced Production Time with Fiber Lasers

Fiber lasers these days can slice through metals three times quicker compared to those old CO2 systems out there. For instance, thin gauge stainless steel gets processed at over twenty meters per minute according to what I read somewhere in the Industrial Laser Report for 2024. The real kicker though is how this increased speed cuts down on waiting around time. Some car makers have actually seen their projects finish about forty percent faster after they ditched plasma cutting methods for fiber lasers instead. Plus, because there's less heat damage around the edges, there's not so much need for extra finishing work afterward. That means factories can just plug these laser machines right into their existing production lines without all sorts of complicated adjustments.

Laser Cutting Efficiency and Speed: Quantifying Throughput Gains

Compared to traditional CO2 options, fiber lasers typically run about 30 percent more efficiently, which means businesses save money on their cutting operations over time. Recent studies looking at companies in the aerospace sector found that switching to these newer systems resulted in roughly 18% quicker turnaround times for jobs and around 22% less electricity usage with those 6 kW models specifically. What makes this possible? The beams are much more focused during operation, plus there's significantly less heat buildup that affects material quality. This combination lets manufacturers keep running non-stop through production cycles while maintaining consistent results across all parts produced.

Real-World Data: 30% Faster Cuts Compared to CO Systems

According to industry standards, fiber lasers can cut through mild steel between 1 and 5 mm thick about 30 to 50 percent quicker compared to traditional CO2 laser systems. Take aluminum sheets as an instance. When working with 3mm thick material, fiber lasers achieve speeds around 8.3 meters per minute whereas CO2 lasers only manage about 5.1 m/min according to the Machining Efficiency Study from last year. The difference becomes even more pronounced when dealing with reflective materials such as copper. Fiber technology keeps going strong without slowing down, something that often plagues CO2 systems due to those pesky beam reflections that cause all sorts of problems during operation.

Metals and Thicknesses Suitable for Fiber Laser Cutting

Fiber lasers excel on conductive metals, handling:

- Stainless steel: Up to 20mm thickness

- Aluminum alloys: Up to 12mm

-

Copper: Up to 8mm

Specialized systems push these limits, with hybrid gas-assisted configurations cutting 30mm steel at 1.2m/min while maintaining ±0.05mm tolerance.

Cutting Stainless Steel, Aluminum, and Copper with Precision

The 1,070nm wavelength of fiber lasers provides 5–10µm spot sizes for clean cuts in reflective metals. A 2023 precision study showed ±0.1mm kerf widths on 3mm stainless steel, enabling tight nesting that reduces material waste by 18–25% compared to plasma cutting.

Limitations in Non-Metallic Materials: Why Fiber Lasers Are Metal-Focused

Fiber wavelengths interact poorly with organics—wood, plastics, and composites absorb less energy, causing incomplete cuts or charring. For these materials, CO lasers (10.6µm wavelength) remain preferable, as their longer waves better interact with molecular structures in non-conductive substrates.

Industrial Applications and Real-World Impact of Fiber Laser Systems

Fiber laser cutting machines have become indispensable in high-stakes manufacturing sectors, delivering accuracy and efficiency unmatched by traditional methods. Their ability to handle complex geometries and ultra-thin materials makes them ideal for industries where micron-level precision directly impacts product performance.

Laser Processing Applications in Automotive and Aerospace Sectors

In automotive manufacturing, fiber lasers reduce cycle times by 22% while cutting 2mm aluminum sheets according to 2023 production data. Aerospace engineers rely on these systems to process titanium alloys and carbon composites for jet engine components, achieving tolerance levels under ±0.05mm — critical for maintaining airflow efficiency in turbine blades.

Precision and Accuracy in Laser Cutting for Medical Device Manufacturing

A 2024 materials study showed fiber lasers reduce edge roughness by 34% compared to mechanical cutting tools when creating surgical instruments. This capability enables mass production of coronary stents with 40µm wall thicknesses, meeting FDA’s stringent surface integrity requirements for implantable devices.

Case Study: Fiber Laser Use in Electric Vehicle Battery Components

When a European EV manufacturer switched to fiber laser systems, they achieved:

- 19% faster tab cutting speeds in lithium-ion battery packs

- 0.3mm alignment consistency across 1.2m-long busbars

- Elimination of copper burrs that previously caused 1.2% cell failures

Controversy Analysis: Is All 'High-Precision' Fiber Cutting Truly Consistent?

While manufacturers often advertise ±0.1mm accuracy, a 2023 cross-industry audit revealed:

- 18% of tested systems exceeded stated tolerances under continuous operation

- Thermal drift caused 0.07mm positional errors after 8 hours in non-climate-controlled environments

These findings underscore the importance of regular calibration and thermal compensation protocols, particularly when cutting reflective materials like copper alloys used in power electronics.

The Future of Fiber Laser Cutting: Automation and Intelligent Integration

Integration of AI and IoT in Laser Cutting Efficiency and Speed

Top manufacturers these days are actually building AI optimization right into their fiber laser systems. These smart systems can tweak cutting settings on the fly depending on how thick the material is, what kind of alloy it contains, even when temperatures in the workshop change throughout the day. Some research published in 2025 showed pretty impressive results too. When factories used machine learning for maintenance predictions, they cut down unexpected stoppages by around 40 percent. And let's not forget about IoT connections either. With these networks, plant managers can keep an eye on all sorts of equipment from one central screen. Workflows get synchronized between different parts of the factory floor, sometimes even linking up operations across entire countries. Makes sense really, given how complex modern manufacturing has become.

Smart Monitoring for Improved Accuracy and Process Stability

Today's fiber laser technology relies on multispectral sensors capable of monitoring over 14 different parameters at once. These include things like focal length stability down to about 0.003mm and gas assist pressure levels. The sensor data gets processed by smart control systems that automatically adjust beam alignment while cutting is happening. This keeps the machine accurate within around 0.02mm positionally throughout long 8 hour operations. Another big improvement comes from thermal compensation algorithms that fight against lens heating issues. Before these were developed, older machines would drift by approximately 0.1mm when running hot, which was a real problem for precision work.

Trend Analysis: The Rise of Fully Autonomous Fiber Laser Workcells

According to industry projections, around two thirds of precision metal fabricators are expected to bring in lights out laser workcells by the end of 2028. The new systems combine robots for moving materials along with smart nesting software powered by artificial intelligence, which gets about 94 percent material usage out of sheets compared to just 82 percent when done manually. Last year's test run showed what these setups can do: they ran non stop for three full days without anyone needing to step in. When problems popped up during this time, like collisions between parts or blocked nozzles, the system handled most issues on its own, fixing roughly nine out of ten potential disruptions without shutting down production at all.

FAQ Section

What are the primary advantages of fiber laser cutting over CO2 laser cutting?

Fiber laser cutting offers increased precision, efficiency, and longevity. It consumes significantly less energy and produces narrower cuts compared to CO2 laser systems.

Which materials are best suited for cutting with fiber lasers?

Fiber lasers excel in cutting conductive metals like stainless steel, aluminum alloys, and copper. They are less suited for organic materials due to energy absorption issues.

How does fiber laser cutting contribute to faster production times?

Fiber lasers can process metals three times faster than CO2 lasers, reducing waiting and production times, and minimizing heat damage, which further decreases post-processing needs.

What innovations are driving the future of fiber laser technology?

Innovations like AI integration and IoT for smart monitoring and predictive maintenance are enhancing fiber laser efficiency, accuracy, and automation capabilities.

What are the limitations of fiber laser cutting technology?

Fiber lasers are less effective with non-metallic materials due to poor interaction with organic molecular structures, necessitating the use of CO2 lasers for such applications.

Table of Contents

- From CO2 to Fiber: A Technological Shift in Laser Cutting

- How Fiber Laser Cutting Machines Redefine Precision and Efficiency

- Key Innovations Driving Fiber Laser Technology Forward

- Unmatched Precision: What Sets Fiber Lasers Apart in Fine Cutting

-

Speed, Efficiency, and Material Capabilities of Fiber Laser Cutting Machines

- Increased Cutting Speed and Reduced Production Time with Fiber Lasers

- Laser Cutting Efficiency and Speed: Quantifying Throughput Gains

- Real-World Data: 30% Faster Cuts Compared to CO Systems

- Metals and Thicknesses Suitable for Fiber Laser Cutting

- Cutting Stainless Steel, Aluminum, and Copper with Precision

- Limitations in Non-Metallic Materials: Why Fiber Lasers Are Metal-Focused

- Industrial Applications and Real-World Impact of Fiber Laser Systems

- The Future of Fiber Laser Cutting: Automation and Intelligent Integration

-

FAQ Section

- What are the primary advantages of fiber laser cutting over CO2 laser cutting?

- Which materials are best suited for cutting with fiber lasers?

- How does fiber laser cutting contribute to faster production times?

- What innovations are driving the future of fiber laser technology?

- What are the limitations of fiber laser cutting technology?