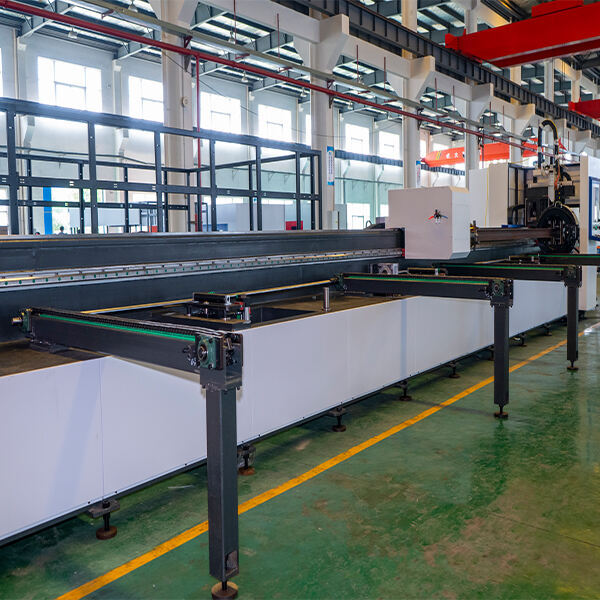

RAYMAX tampil menonjol sebagai pemasok mesin pemotong laser serat yang terpercaya, didukung oleh pengalaman manufaktur selama 22 tahun, basis pelanggan global yang mencakup lebih dari 4000 klien, serta komitmen terhadap dukungan dari awal hingga akhir—mulai dari desain mesin hingga layanan purna jual. Posisi kami sebagai pemasok ditentukan oleh tiga keunggulan utama: kontrol manufaktur internal, kemampuan logistik global, dan kustomisasi berdasarkan industri—semuanya dirancang untuk memenuhi kebutuhan industri otomotif, penerbangan, galangan kapal, energi, dan petrokimia. Manufaktur & Kontrol Kualitas Internal memastikan keandalan. Berbeda dengan pemasok yang memproduksi secara outsourcing, kami memproduksi setiap mesin pemotong laser serat di pabrik seluas 20.000㎡ kami, di mana 60% dari 400 staf kami merupakan tenaga teknis menengah hingga senior. Integrasi vertikal ini memungkinkan kami mengontrol setiap tahap: mulai dari pengadaan komponen berkualitas tinggi (misalnya sumber laser IPG, motor servo Siemens) hingga pelaksanaan 12 uji kualitas ketat sebelum pengiriman. Sebagai contoh, setiap mesin menjalani uji pemotongan berkelanjutan selama 100 jam—kami memotong lebih dari 100 lembar pelat baja karbon dan aluminium untuk memverifikasi ketepatan (±0,05mm), kecepatan, dan stabilitas. Seorang klien otomotif di Asia Tenggara memuji perhatian pada kualitas ini: mesin pemotong laser serat 3000W mereka telah beroperasi secara berkelanjutan selama 3 tahun dengan pemeliharaan minimal, memotong lebih dari 10.000 komponen rangka kendaraan setiap bulannya. Logistik Global & Dukungan Lokal menjadikan kami pemasok yang dapat diakses di seluruh dunia. Kami mengekspor mesin pemotong laser serat ke Asia Tenggara, Timur Tengah, Eropa Barat, dan Amerika Selatan, dengan jaringan mitra lokal yang menangani proses bea cukai, pengiriman, dan pemasangan di lokasi. Untuk klien penerbangan di Eropa Barat, kami berkoordinasi dengan perusahaan logistik lokal untuk mengirimkan mesin pemotong laser serat dengan panjang meja 6 meter (untuk pelat fuselage aluminium besar) dan mengirimkan tim teknisi berjumlah 3 orang untuk merakit serta mengkalibrasi mesin—memastikan mesin beroperasi dalam waktu 5 hari. Dukungan global kami tidak berakhir pada pemasangan: kami menyediakan dukungan teknis 24/7 melalui saluran bebas pulsa, panggilan video, dan kunjungan lapangan (dalam waktu 48 jam untuk masalah mendesak di wilayah utama). Baru-baru ini, sebuah klien pembangkit listrik di Timur Tengah mengalami gangguan perangkat lunak—tim kami berhasil menyelesaikannya secara jarak jauh dalam waktu 1 jam, meminimalkan waktu henti pemotongan penyangga ketel baja. Keahlian Spesifik Industri membedakan kami dari pemasok umum. Kami tidak hanya menjual mesin—kami menyediakan solusi yang disesuaikan dengan sektor Anda. Untuk klien otomotif yang memotong pelat baja berkekuatan tinggi, kami menyediakan mesin dengan laser berdaya tinggi (4000W+) dan perangkat lunak nesting untuk mengoptimalkan penggunaan material. Untuk klien penerbangan yang memotong paduan aluminium tipis (0,5-3mm), kami menawarkan mesin dengan panduan linear ultra-akurat (ketelitian ±0,03mm) dan sistem pengumpulan debu untuk menghindari kontaminasi. Seorang klien galangan kapal di Indonesia membutuhkan mesin untuk memotong pelat baja tahan karat tebal (15mm) untuk komponen pipa—kami menyesuaikan mesin dengan kepala pemotong bertekanan tinggi dan rangka tahan korosi, memastikan kinerjanya tetap andal dalam kondisi pesisir. Sebagai pemasok, kami juga mengutamakan kemitraan jangka panjang. Kami menyediakan pelatihan operator (di lokasi dan daring) untuk memastikan tim Anda memaksimalkan kemampuan mesin—sebagai contoh, mengajarkan klien industri ringan untuk menggunakan perangkat lunak nesting sehingga dapat mengurangi limbah material sebesar 12%. Kami juga menyediakan gudang suku cadang regional (di Asia Tenggara, Eropa Barat, dan Timur Tengah) untuk mengirimkan komponen penting (misalnya nosel laser, lensa) dalam waktu 2-3 hari, meminimalkan waktu henti operasional. Baik Anda sebuah bengkel industri ringan berskala kecil maupun produsen penerbangan berskala besar, RAYMAX menyediakan keandalan, dukungan, dan kustomisasi yang Anda butuhkan dari seorang pemasok mesin pemotong laser serat.