1.Press brake features a 400-ton bending force and a 4-meter bed length, enabling it to handle large and thick metal sheets.

2.Hydraulic Press brake with 8+1 axis, refers to its advanced CNC Delem control system, which automates the adjustment of the back gauge and slipper height.

3.Press brake combined with a precise hydraulic servo control system, high-resolution grating ruler feedback, and an automated back gauge, which can achieve positioning accuracy and repeatability, meeting the production needs of large quantities and high requirements.

4.Press brake uses high-performance hydraulic servo pumps and proportional valves, precise control of slider speed, pressure, and position can be achieved.

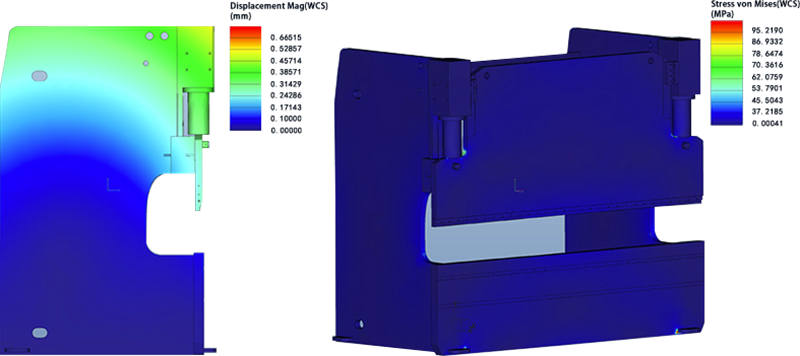

The machine frame is constructed from a fully welded and precision-machined structure, with critical components analyzed using ANSYS finite element analysis to ensure structural reliability and overall machining accuracy. Each press brake is built on a strong, one-piece base made of high-quality, high-strength steel, guaranteeing consistent and dependable performance year after year.

Type |

Nominal pressure (KN) |

Workbench length (mm) |

Workbench width (mm) |

Poles distance (mm) |

Throat depth (mm) |

Main motor (kw) |

Dimensions L*W*H (mm) |

40*1600 |

400 |

1600 |

900 |

1165 |

350 |

5.5 |

2250*1650*2400 |

63*2500 |

630 |

2500 |

900 |

1960 |

380 |

5.5 |

3150*1700*2500 |

80*2500 |

800 |

2500 |

900 |

1960 |

380 |

7.5 |

3150*1700*2500 |

80*3200 |

800 |

3200 |

900 |

2760 |

380 |

7.5 |

3850*1700*2500 |

100*3200 |

1000 |

3200 |

950 |

2750 |

390 |

7.5 |

3900*1800*2650 |

125*3200 |

1250 |

3200 |

950 |

2750 |

390 |

11 |

3900*1800*2680 |

160*3200 |

1600 |

3200 |

1000 |

2740 |

400 |

15 |

4000*1900*2720 |

200*3200 |

2000 |

3200 |

1000 |

2730 |

400 |

18.5 |

4000*1900*2720 |

300*3200 |

3000 |

3200 |

1330 |

2720 |

500 |

22 |

4000*2200*3500 |

100*4000 |

1000 |

4000 |

950 |

3350 |

390 |

7.5 |

4800*1800*2650 |

125*4000 |

1250 |

4000 |

950 |

3350 |

390 |

11 |

4800*1800*2680 |

160*4000 |

1600 |

4000 |

1000 |

3340 |

400 |

15 |

4800*1900*2720 |

200*4000 |

2000 |

4000 |

1000 |

3330 |

400 |

18.5 |

4800*1900*2800 |

250*4000 |

2500 |

4000 |

1000 |

3330 |

450 |

18.5 |

4800*1900*2850 |

It equipped with a 24 inch high-resolution color TFT display screen, supports 2D/3D graphical touch programming, has 3D machine model visualization function, and integrates Profile S3D offline programming software to achieve efficient and intuitive operation and programming experience.

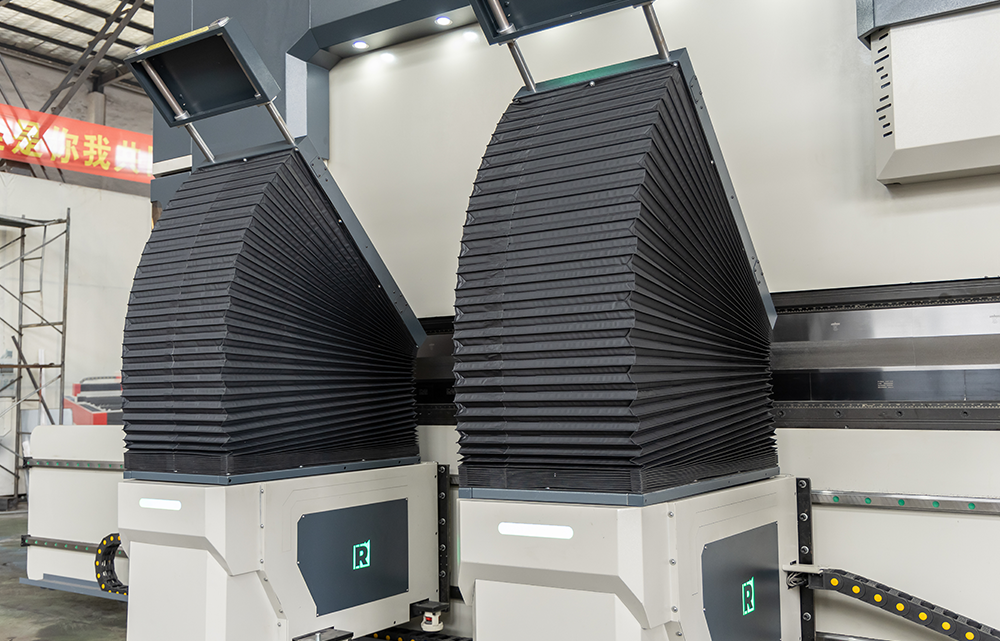

Back Gauge with 6 axis (X1, X2, Z1, Z2, R1, R2) can achieve precise and flexible positioning of the workpiece. Ensure the accuracy of long workpieces and ensure uniform bending angles throughout the entire length.

Using the pressure generated by a hydraulic system to automatically clamp or release workpieces, characterized by rapid action, precise positioning.

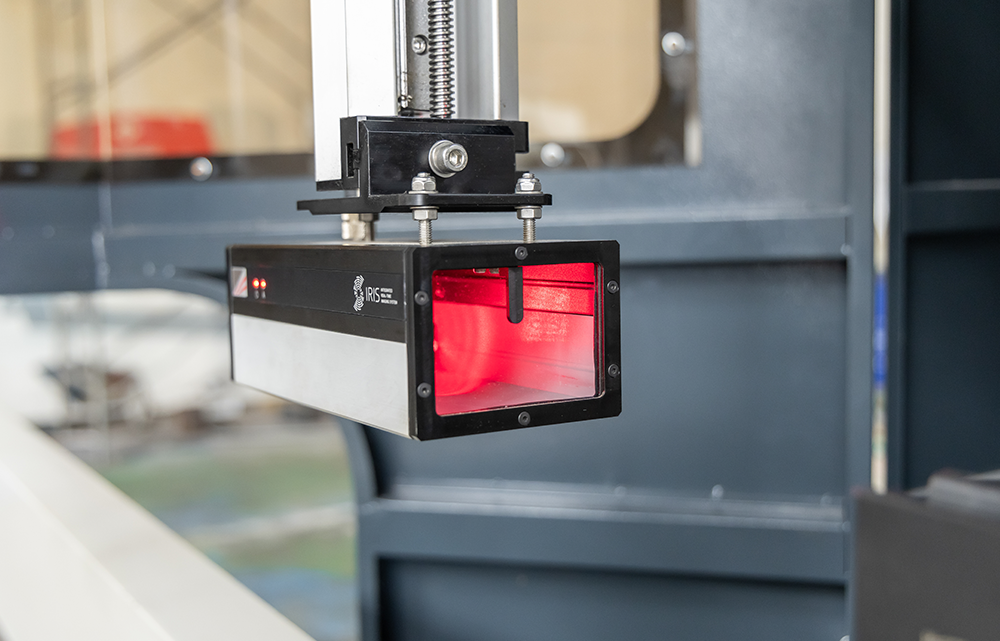

Lazersafe IRIS device comprehensively protects the personal safety of bending machine operators and avoids danger due to the rapid movement of the slider on the machine. Once an obstruction enters the Lazersafe IRIS protection zone, it will immediately send a signal and interrupt the downward movement of the slider.

Implemented through distress programming deflection to counteract any possible deflection under load or compensate for any tool wear, ensuring that the contact surfaces under load are parallel to each other.

Recommended for heavy plates or large and thin plates. Support long workpieces to prevent sagging. Improve operational safety, bending accuracy, and consistency. Cooperate with the rear stopper to achieve precise positioning.

Reliable hydraulic transmission and an integrated hydraulic unit work together to reduce the impact of fluid leaks.

Realize high-precision, high-speed, and controllable driving of various motion axes in the bending machine, thereby ensuring the accuracy, repeatability, and automation level of the bending process. Reduce oil consumption and achieve high cleanliness. Reduce noise. Save energy by over 25% and improve work efficiency.

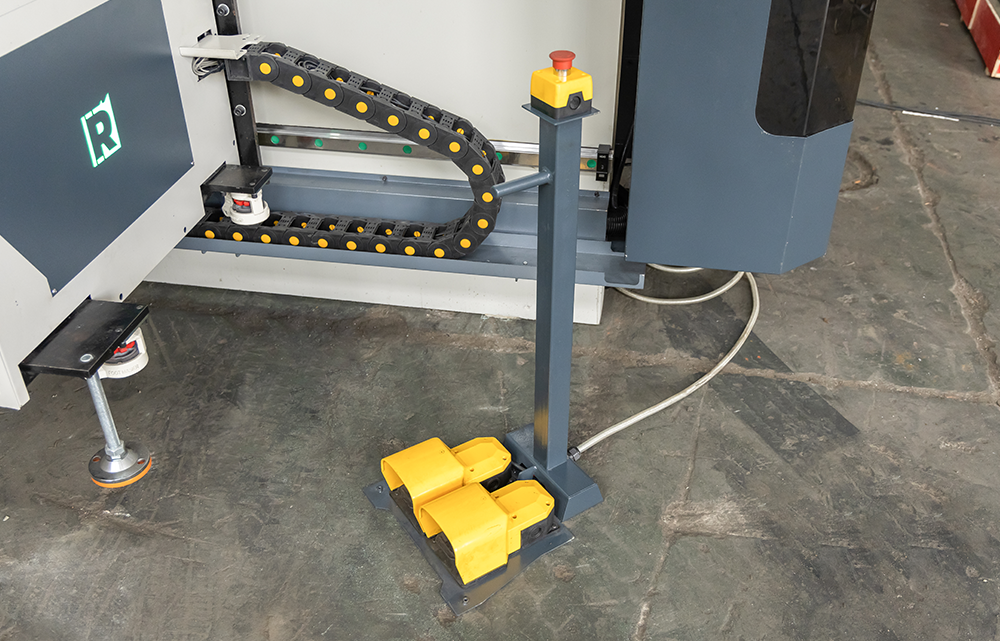

Controlling the machine through the feet, both hands can operate freely while safely and accurately controlling the bending process.

Single V-die can provide precise support and a benchmark for bending and forming of the sheet metal, ensuring consistency in bending angle, inner fillet, and size.