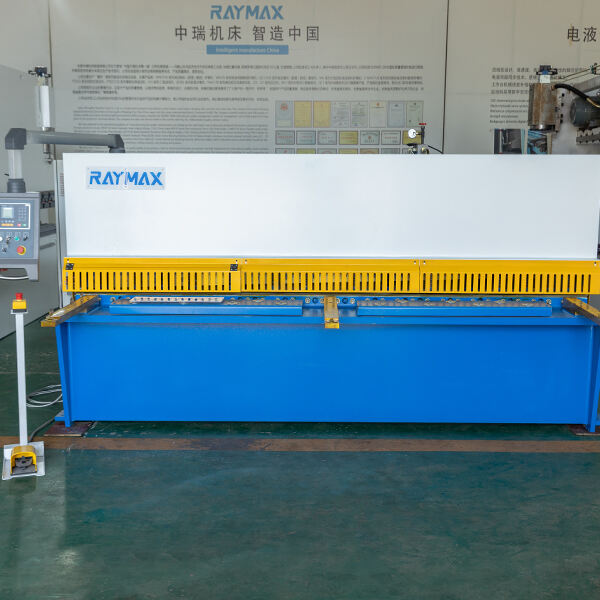

A CNC hydraulic shearing machine supplier plays a vital role in the metal fabrication industry by providing advanced machines that combine the precision of CNC technology with the power of hydraulic systems. These suppliers source their machines from reputable manufacturers that specialize in designing and building high-performance shearing equipment. CNC hydraulic shearing machines are equipped with sophisticated control systems that allow operators to program complex cutting patterns and sequences, enabling the production of intricate shapes and components with minimal manual intervention. The hydraulic system, on the other hand, provides the necessary force to cut through thick metal sheets and profiles with ease, ensuring clean and precise cuts every time. One of the key advantages of working with a CNC hydraulic shearing machine supplier is the access to a wide range of machine models and configurations, allowing customers to choose the one that best fits their production needs and budget. Additionally, these suppliers often offer value-added services such as installation, training, and technical support, ensuring a smooth transition to the new equipment and ongoing operational efficiency. For example, a supplier might provide on-site training for operators, covering topics such as CNC programming, machine operation, and maintenance, helping customers maximize the potential of their investment. In a real-world application, a metal fabrication shop that upgraded to a CNC hydraulic shearing machine from a reputable supplier was able to increase its cutting speed by 40% and reduce material waste by 25%, resulting in significant cost savings and improved competitiveness. For businesses looking to invest in CNC hydraulic shearing machines, choosing a reliable supplier is essential for ensuring a successful and profitable outcome.