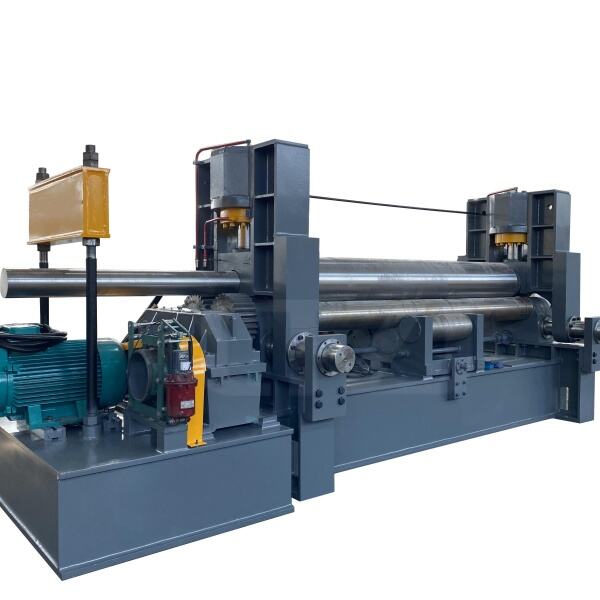

Roll forming and rolling machines are complementary technologies used to shape metal sheets or strips into continuous profiles with consistent cross-sections. Roll forming machines pass material through a series of paired rollers, each progressively bending the metal until the desired shape is achieved, making them ideal for producing long components like roofing panels, door frames, and automotive channels. Rolling machines, on the other hand, apply force to deform metal into curved or cylindrical forms, commonly used in pipe manufacturing, pressure vessel fabrication, and architectural cladding. A hybrid approach combines both technologies—for example, a roll-forming line may incorporate a pre-bending rolling station to create closed profiles without welds, enhancing structural integrity. In a case study, a solar panel manufacturer utilized a custom roll-forming system with integrated rolling capabilities to produce lightweight, corrosion-resistant mounting structures. The machine’s modular design allowed quick adaptation to varying profile dimensions, reducing setup time by 50% compared to standalone systems. Advanced roll-forming machines now feature digital twinnning, enabling virtual simulation of production processes to validate tooling designs before physical implementation. This minimizes trial-and-error adjustments, ensuring first-article accuracy even for complex geometries. For industries requiring high-volume, low-tolerance parts, the synergy between roll forming and rolling technologies offers unmatched efficiency and versatility.