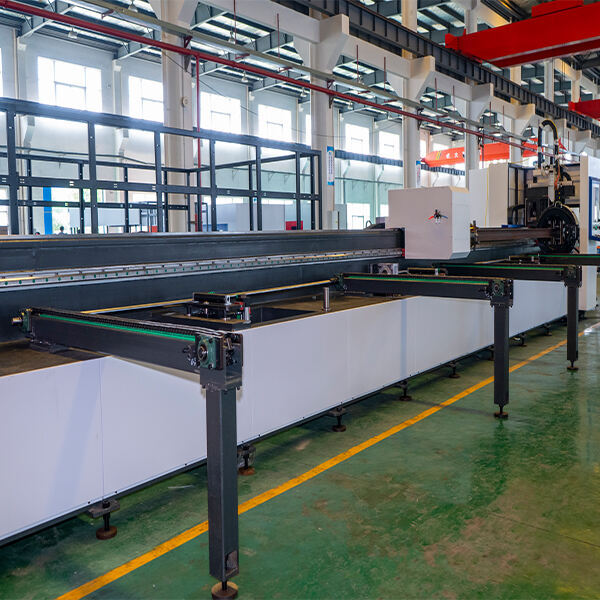

تُعد RAYMAX من أبرز موردي آلات قطع الليزر الليفية الموثوقة، بفضل خبرة تصنيع تمتد على مدى 22 عامًا، وقاعدة عملاء عالمية تضم أكثر من 4000 عميل، والتزامها بتوفير دعم شامل يمتد من تصميم الآلة إلى الخدمة ما بعد البيع. ويتم تحديد مكانتنا كمورد من خلال ثلاث نقاط قوة أساسية: التحكم في التصنيع داخليًا، والقدرات اللوجستية العالمية، والتخصيص حسب القطاع الصناعي — وكلها مصممة خصيصًا لتلبية احتياجات قطاعات السيارات والطيران وبناء السفن والطاقة والصناعات البتروكيماوية. يضمن التصنيع الداخلي ومراقبة الجودة الموثوقية. وعلى عكس الموردين الذين يستعينون بشركات خارجية للإنتاج، فإننا نقوم بتصنيع كل آلة قطع ليزر ليفية داخل مصنعنا البالغ مساحته 20,000 متر مربع، حيث يعمل 60% من موظفينا البالغ عددهم 400 موظفًا في وظائف فنية متوسطة أو عليا. وتتيح لنا هذه التكاملية الرأسية التحكم في كل خطوة بدءًا من توريد مكونات عالية الجودة (مثل مصادر الليزر IPG، ومحركات سيرفو Siemens) وصولاً إلى إجراء 12 فحصًا صارمًا للجودة قبل التسليم. على سبيل المثال، تخضع كل آلة لاختبار قطع مستمر لمدة 100 ساعة — حيث نقوم بقطع أكثر من 100 لوحة من الفولاذ الكربوني والألومنيوم للتحقق من الدقة (±0.05 مم) والسرعة والاستقرار. وقد أشاد أحد العملاء في جنوب شرق آسيا من قطاع السيارات بهذه العناية بالجودة: إذ استمرت آلة القطع بالليزر الليفي بقدرة 3000 واط في العمل بشكل متواصل لمدة 3 سنوات مع الحد الأدنى من الصيانة، وقامت بقطع أكثر من 10,000 مكون هيكل شهريًا. إن الخدمات اللوجستية العالمية والدعم المحلي تجعلنا موردًا سهل الوصول إليه في جميع أنحاء العالم. نحن نصدر آلات قطع الليزر الليفية إلى جنوب شرق آسيا والشرق الأوسط وأوروبا الغربية وأمريكا الجنوبية، مع شبكة من الشركاء المحليين لتسيير إجراءات الجمارك والشحن والتثبيت الميداني. بالنسبة لعميل في قطاع الطيران بأوروبا الغربية، تعاونّا مع شركة لوجستية محلية لتسليم آلة قطع ليزر ليفية ذات سرير بطول 6 أمتار (لأغراض قطع صفائح الألومنيوم الكبيرة الخاصة بالهيكل) وأرسلنا فريقًا مكوّنًا من 3 فنيين لتجميع وضبط الآلة — مما ضمن تشغيلها خلال 5 أيام فقط. ولا ينتهي دعمنا العالمي عند مرحلة التثبيت: نحن نقدم دعمًا فنيًا على مدار الساعة طوال أيام الأسبوع عبر الخط الساخن ومكالمات الفيديو والزيارات الميدانية (خلال 48 ساعة في حالة المشكلات العاجلة في المناطق الرئيسية). ومؤخرًا، واجه أحد عملائنا في محطة توليد كهرباء بالشرق الأوسط خللًا برمجيًا — وتمكن فريقنا من حل المشكلة عن بُعد خلال ساعة واحدة، مما حدّ من توقف عمليات قطع دعامات الغلايات الفولاذية. أما الخبرة المتخصصة حسب القطاع فهي ما يميزنا عن الموردين العامين. نحن لا نبيع الآلات فحسب، بل نقدم حلولًا مصممة خصيصًا لقطاعك. بالنسبة للعملاء في قطاع السيارات الذين يقومون بقطع صفائح الفولاذ عالي القوة، نوفر آلات مزودة بليزر عالي الطاقة (4000 واط فأكثر) وبرمجيات ترتيب (nesting) لتحسين استخدام المواد. وبالنسبة للعملاء في قطاع الطيران الذين يقومون بقطع سبائك الألومنيوم الرقيقة (0.5-3 مم)، نقدم آلات مزودة بإرشادات خطية فائقة الدقة (بدقة ±0.03 مم) وأنظمة جمع للغبار لتجنب التلوث. وكان أحد عملائنا في حوض بناء السفن بإندونيسيا بحاجة إلى آلة لقطع ألواح الفولاذ المقاوم للصدأ السميكة (15 مم) لمكونات الأنابيب — فقمنا بتخصيص الآلة برأس قطع عالي الضغط وإطار مقاوم للتآكل، مما كفل أداؤها الموثوق في الظروف الساحلية. وبصفتنا موردًا، فإننا نولي أولوية أيضًا للشراكات طويلة الأمد. نحن نوفر تدريبًا للمشغلين (مباشرًا وعن بُعد) لضمان تحقيق فريقكم لأقصى استفادة من إمكانات الآلة — على سبيل المثال، قمنا بتدريب عميل من قطاع الصناعة الخفيفة على استخدام برنامج الترتيب لتقليل هدر المواد بنسبة 12%. كما نحافظ على مستودعات إقليمية لقطع الغيار الاحتياطية (في جنوب شرق آسيا وأوروبا الغربية والشرق الأوسط) لتوصيل المكونات الحرجة (مثل فوهات الليزر والعدسات) خلال يومين إلى ثلاثة أيام، مما يقلل من توقف العمليات. سواء كنت ورشة صغيرة في قطاع الصناعة الخفيفة أو مصنّعًا كبيرًا في قطاع الطيران، فإن RAYMAX توفر لك الموثوقية والدعم والتخصيص الذي تحتاجه من مورد آلات قطع الليزر الليفية.