Understanding the Role of the Focusing Lens in Fiber Laser Cutting Machines

What is a Focusing Lens in Fiber Laser Systems?

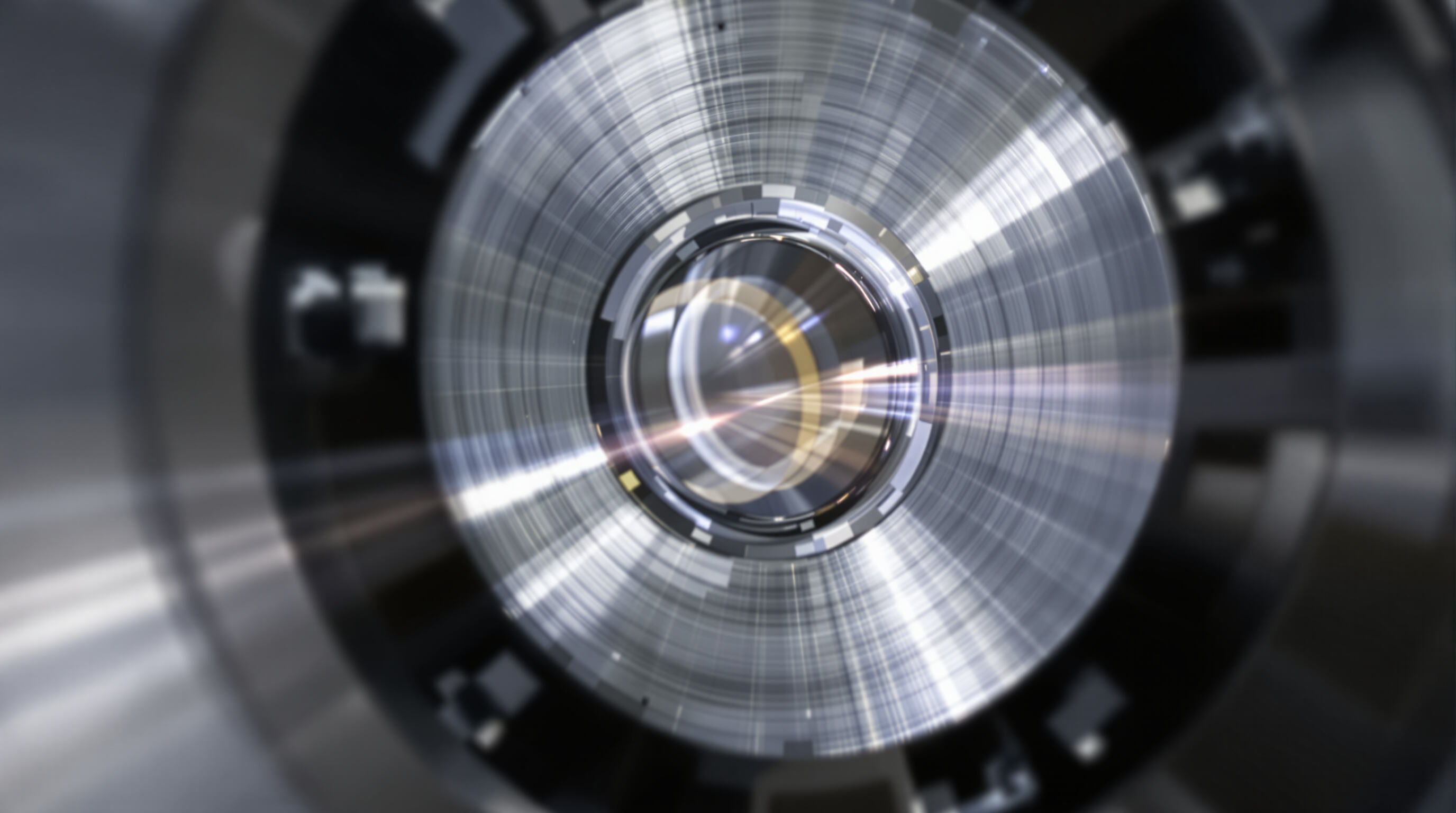

Focusing lenses in fiber laser systems gather scattered laser light and concentrate it at a single high-energy point, creating energy densities that can go beyond 1 million watts per square millimeter. These lenses are usually constructed from materials like zinc selenide (ZnSe) or fused silica, which help turn those spread out beams into tiny spots just a few microns across. This is what makes material vaporization possible during cutting operations. The surfaces of these lenses need to be ground with incredible precision, often down to lambda over ten wavefront errors, so they don't distort the beam as it passes through. Such attention to detail ensures reliable results whether working with smaller 1 kilowatt lasers or larger industrial units generating up to 20 kilowatts of power.

Importance of Focusing Lens in Laser Cutting Performance

A properly specified focusing lens improves cutting speed by 15–40% and reduces kerf width by up to 30% compared to degraded optics (Laser Institute of America, 2023). Key performance drivers include:

- Transmission efficiency: High-purity ZnSe maintains 99.5% transmission at 10.6 μm wavelengths

- Thermal stability: Fused silica withstands 1,000°C surface temperatures without warping

- Material compatibility: Optimal focal lengths mitigate aluminum reflectivity and stainless steel oxidation

How the Focusing Lens Shapes Laser Beam Precision and Accuracy

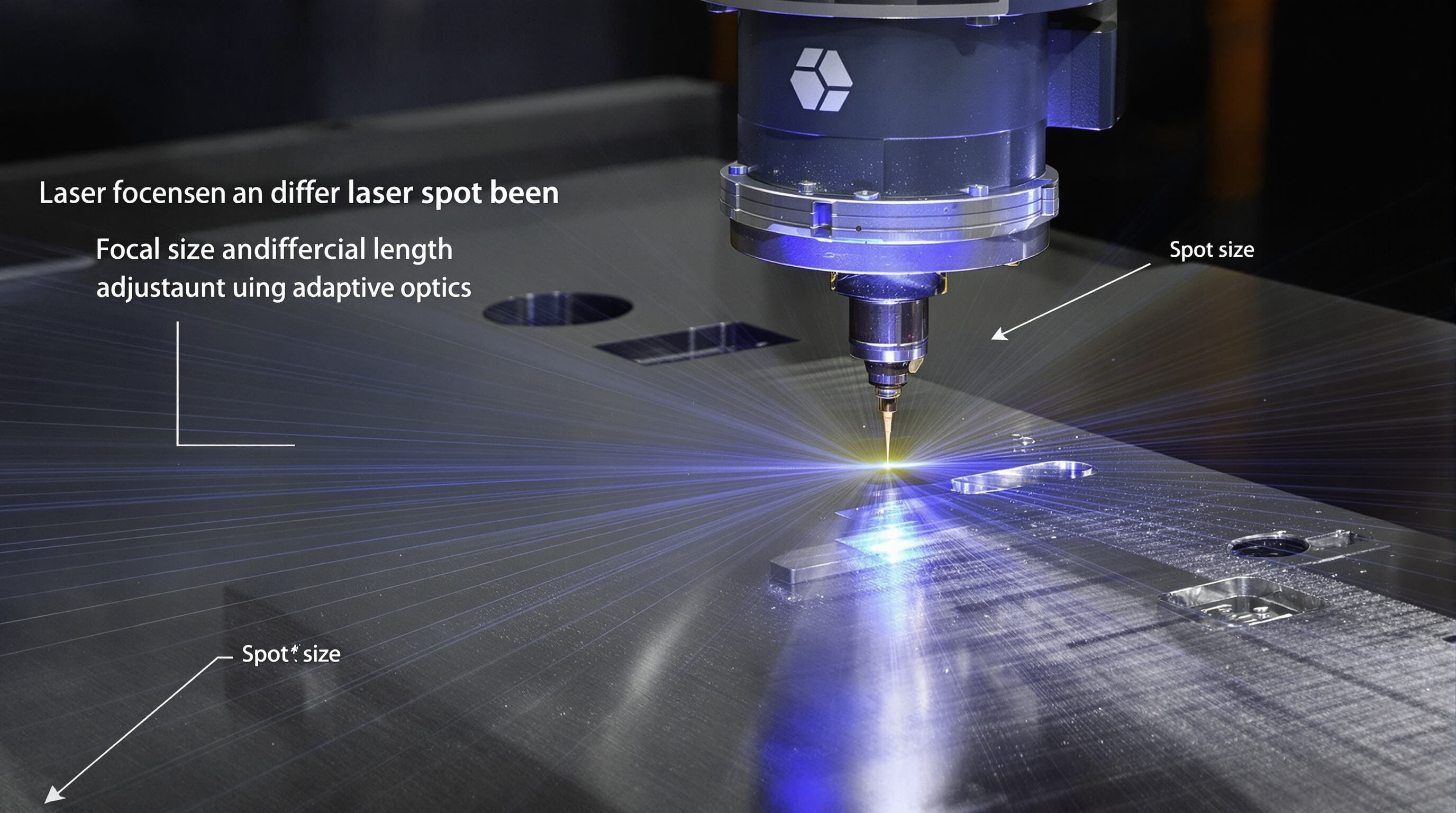

The focal length plays a big role in determining the spot size created during processing. For instance, when working with thin sheet metals, a 2.5 inch lens creates around a 100 micrometer spot. But if we switch to thicker materials like 25 mm carbon steel, then a 5 inch lens becomes necessary as it produces approximately 300 micrometers spot size instead. Most modern CNC machines come equipped with features that allow them to fine tune the focus position within plus or minus half a millimeter range depending on how thick the material actually is. Recent testing has shown some promising results too. When manufacturers started using these specially designed lenses, they noticed a significant drop in dross formation on stainless steel parts by nearly three quarters. At the same time, these systems maintained impressive precision levels throughout entire eight hour shifts, keeping positional errors below five hundredths of a millimeter consistently across all operations.

Types and Materials of Focusing Lenses for Fiber Laser Cutting Machines

Common Lens Types: Plano-Convex vs. Meniscus and Their Optical Characteristics

The industrial world relies heavily on plano-convex lenses because of their unique shape flat on one side and curved on the other. These lenses manage to focus around 98 percent of laser energy into a tiny spot measuring less than 0.2 mm according to research published in the Optics & Photonics Journal back in 2023. When it comes to meniscus lenses though things get interesting. With both sides curved these optical components cut down spherical aberrations somewhere between 30 to 40 percent. That makes them particularly good for those tricky aerospace cutting jobs where complex shapes need precise handling. Manufacturers working with intricate parts often find themselves turning to meniscus designs when accuracy matters most.

Key Lens Materials: ZnSe, CaF2, and Fused Silica in High-Power Applications

Zinc Selenide (ZnSe) is still widely used for mid-range CO2 lasers because it transmits about 99.5% of light at 10.6 microns, though it starts breaking down pretty quickly once power exceeds 4 kilowatts. For those working with higher power levels, Calcium Fluoride (CaF2) materials last roughly 60% longer in these multi-kW fiber systems. Meanwhile, when dealing with ultra short pulses under one picosecond, fused silica stands out due to its better heat handling properties. Choosing the right material isn't just about numbers on paper either. The decision really depends on what kind of laser setup someone has, how much power they need to handle regularly, and whether their application requires continuous operation or intermittent bursts.

Durability vs. Transmission Efficiency: Trade-Offs in Material Selection

Industrial users face critical trade-offs:

- ZnSe costs 40% less than CaF2 but requires replacement three times more often in continuous operations

- Fused silica withstands temperatures above 150°C but sacrifices 2–3% transmission efficiency

- Diamond-coated lenses (emerging technology) offer 10,000-hour lifespans at five times the cost

A recent automotive laser cutting analysis found that strategic material switching reduced per-part lens costs by 19% when processing mixed metals.

Focal Length, Spot Size, and Focus Position: Optimizing Cut Quality

Focal length selection: Short vs. long for different materials and thicknesses

When working with thinner materials under 4mm thick, shorter lenses between about 2.5 to 5 inches create those tiny spots needed for accurate cuts. The real magic happens with thicker steel plates ranging from 8 to 20mm though. Here, going up to around 7.5 to 10 inch focal lengths makes all the difference. These longer lenses give better depth control so the laser stays stable across the entire cut surface. Research from manufacturing sectors indicates that getting this match right between what's being cut and the lens used can boost productivity anywhere from 15% to nearly a quarter improvement in some cases. Makes sense really since mismatched equipment just wastes time and resources.

Spot size and its impact on cutting precision and penetration depth

The smaller 0.1 mm spot size actually gives us about 2 to 3 times more power density compared to the bigger 0.3 mm beam. This makes all the difference when we need clean cuts and narrow kerfs for detailed work like engraving. When working with larger spot sizes ranging from 0.25 to 0.4 mm, something interesting happens too. These bigger spots can penetrate deeper into materials, increasing the depth by roughly 40% in 12 mm aluminum alloys. The result? Less slag sticking to the material surface during processing. Modern equipment now comes equipped with adaptive optics technology that constantly tweaks the spot size as needed. This keeps edges within tight tolerances of plus or minus 0.02 mm throughout entire production batches, which is pretty impressive considering how consistent it stays run after run.

Focus position adjustment for varying material thicknesses

For materials under 6 mm, placing the focal point at the surface minimizes heat distortion. When cutting 15 mm stainless steel, lowering the focus 2–3 mm below the surface enhances energy distribution, reducing dross by up to 70%. Capacitive height sensors now enable real-time focus adjustments, compensating for warping during high-speed operations.

Case study: Stainless steel vs. aluminum cutting optimization

Looking at how 3 mm thick 304 stainless steel compares to 5052 aluminum shows some pretty different needs for cutting. The stainless steel works best when cutting at around 6 meters per minute with a 5 inch focal length lens positioned about 0.8 mm above the material surface. Things get trickier with aluminum though because it reflects so much light. We found that switching to a 3.5 inch lens and moving it down 1.2 mm below the material helps overcome this reflection problem. These adjustments actually cut down on energy use by nearly 20 percent, which is quite impressive considering we still managed to keep the surface finish quality around Ra 3.2 micrometers for both metals. Makes sense why manufacturers would want to know these differences when setting up their laser cutting operations.

Maintenance and Inspection of Focusing Lenses in Fiber Laser Systems

Best Practices for Cleaning Focusing Lenses and Preserving Optical Integrity

Keeping up with regular maintenance work helps avoid those frustrating power losses and keeps lenses working longer than they otherwise would. When checking lenses, always do it under good lighting conditions with at least 10 times magnification. Even tiny particles around 0.1 mm in size can actually scatter about 15% of the laser's energy according to Industrial Laser Report from last year. Start cleaning by blowing away any loose stuff with compressed dry air first. Then grab those optical grade wipes and move them in circles starting from the middle outwards toward the edges. The payoff for all this careful attention? Businesses report saving roughly 40% on their yearly replacement expenses while still maintaining that critical ±0.01 mm precision needed for accurate cuts.

Dry Cleaning vs. Solvent-Based Methods: Industrial Pros and Cons

| Method | Advantages | Limitations | Ideal Use Cases |

|---|---|---|---|

| Dry Cleaning | - No chemical residue - Fast process (≈2 mins) |

- Less effective on oils - Requires compressed air >6 bar |

Daily maintenance on low-fume materials |

| Solvent-Based | - Removes stubborn deposits - Disinfects surfaces |

- Risk of coating damage - Requires 15+ mins drying time |

Monthly deep cleaning in high-smoke environments |

Routine Inspection of Lenses and Mirrors to Prevent Beam Degradation

Implement weekly optical inspections using a standardized checklist:

- Surface scratches >0.3 mm diameter – replace immediately

- Thermal distortion patterns – monitor lens temperature during operation

- Coating degradation at edges – affects 8–12% beam uniformity

- Particulate accumulation – clean when deposits exceed 5% surface coverage

Quarterly interferometer testing detects focal length deviations beyond manufacturer tolerances, a common precursor to cut quality issues.

Troubleshooting and Replacing the Focusing Lens in Fiber Laser Cutting Machines

Signs of Lens Degradation: Reduced Cut Quality, Beam Distortion, and Power Loss

There are three main signs operators need to watch out for when checking lens condition. First up, poor cutting results show themselves through uneven kerf widths or too much dross buildup, particularly noticeable when working with materials like stainless steel and aluminum sheets. Then there's the issue of beam distortion, which creates those telltale oval shaped spots instead of round ones, leading to lower energy concentration at the workpiece. And finally, most technicians will know something's wrong when they see power levels drop around 20 to maybe even 30 percent below normal readings. That kind of decline is usually a red flag for worn lenses and means it's time to pull them out for close examination before any serious damage occurs.

Common Causes of Lens Failure in Industrial Fiber Laser Environments

Thermal stress from prolonged high-power use (6 kW+) is the leading cause of premature failure. Metal vapor contamination in automotive environments creates micro-fractures in coatings. Maintenance logs show 67% of unplanned replacements result from mechanical misalignment during nozzle changes or collisions. In humid climates, moisture accelerates ZnSe degradation through hydrolysis.

Replacement Strategy: Balancing Cost, Downtime, and Performance Recovery

Changing out components proactively around the 300 to 400 hour mark for those 10 kW systems cuts down on unexpected downtime by about 40 something percent when compared with waiting until things break down. For lenses, go with ones that have these special hybrid coatings which maintain pretty much all the light transmission – we're talking over 99.5% at that 1070 nm wavelength. When it comes time to swap them out, cross trained tech crews generally finish the job within just 18 minutes flat, which beats what one person could manage by roughly a third. Once everything's installed, don't forget to adjust the focal point since those new lenses might vary slightly in thickness, keeping that variation within plus or minus 0.1 mm is important. And while storing spare parts, make sure they're kept in those nitrogen filled containers to keep dust and other contaminants away from sensitive surfaces.

Key protocol: Always recalibrate cutting parameters post-replacement, as focal length changes directly affect kerf width (±0.05 mm precision) and piercing speed thresholds.

FAQ Section

What are the main components of a focusing lens in fiber laser systems?

Focusing lenses are typically made from materials like zinc selenide (ZnSe) or fused silica, which help concentrate scattered laser light into high-energy points for efficient cutting operations.

How does the focal length impact laser cutting performance?

The focal length affects the spot size created during processing, influencing cutting precision and penetration depth. Short focal lengths are ideal for thin materials, while longer ones are suitable for thicker plates.

Why is maintaining the focusing lens essential?

Regular maintenance of focusing lenses prevents power losses and ensures precise cuts, saving on replacement costs and enhancing operational efficiency.

What are the signs of lens degradation in fiber laser cutting machines?

Lens degradation is often indicated by poor cutting results, uneven kerf widths, beam distortion, and unexpected power loss.

How should focusing lenses be cleaned?

Focusing lenses should be cleaned using dry methods with compressed air or solvent-based methods for removing stubborn deposits, ensuring optical integrity is preserved.

Table of Contents

- Understanding the Role of the Focusing Lens in Fiber Laser Cutting Machines

- Types and Materials of Focusing Lenses for Fiber Laser Cutting Machines

- Focal Length, Spot Size, and Focus Position: Optimizing Cut Quality

- Maintenance and Inspection of Focusing Lenses in Fiber Laser Systems

- Troubleshooting and Replacing the Focusing Lens in Fiber Laser Cutting Machines

- FAQ Section