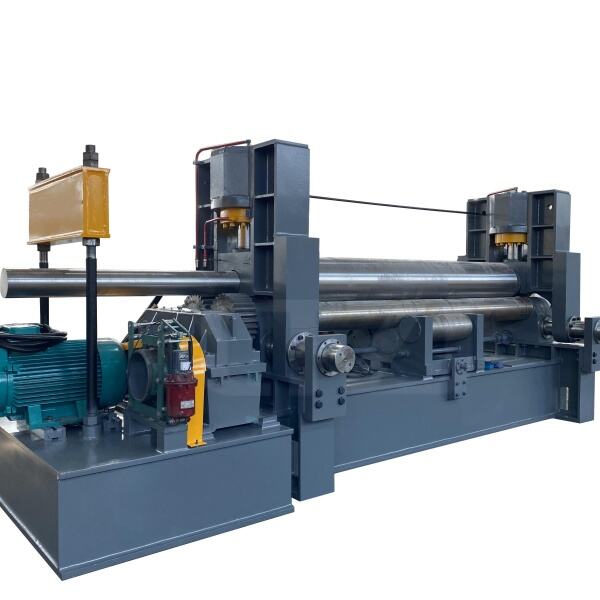

Rolling machines are categorized based on their design, function, and application, with the primary types being 2-roll, 3-roll, and 4-roll machines, each offering distinct advantages. 2-roll machines are the simplest, consisting of two parallel rollers that pinch and bend material through friction. They are cost-effective for light-duty tasks like forming thin metal sheets into simple curves but lack precision for complex geometries. 3-roll machines add a third roller, either positioned above the two bottom rollers (initial-pinch) or between them (pyramid-style), enabling better control over pre-bending and reducing the flat end typically left by 2-roll systems. These are widely used in HVAC and automotive industries for producing cones and cylinders. 4-roll machines introduce a fourth roller, which acts as a backgauge to eliminate flat ends entirely and improve bending accuracy. They are ideal for high-precision applications like pressure vessel fabrication and architectural cladding, where tight tolerances are mandatory. Specialized variants include plate rolling machines for heavy-duty steel processing and section rolling machines designed for I-beams or angle iron. Hydraulic and mechanical power sources further differentiate models; hydraulic systems offer smoother force application and are preferred for thick materials, while mechanical rollers are faster and more economical for thin gauges. Choosing the right type depends on factors like material thickness, production volume, and desired bend quality—our experts can guide you through this selection process to ensure optimal performance.