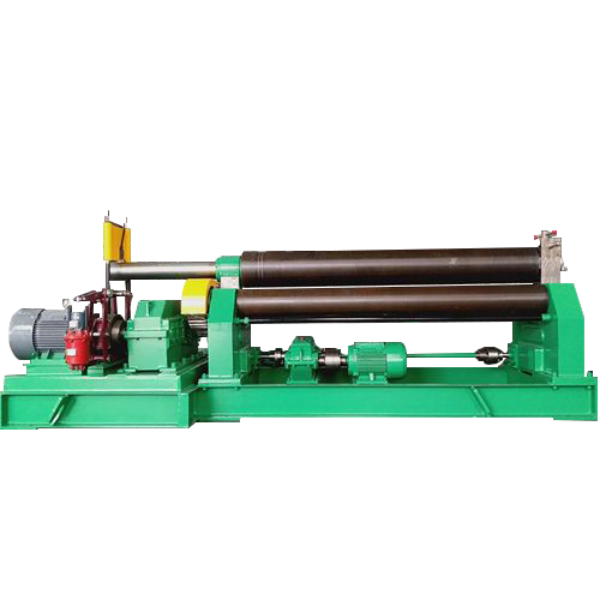

A precision rolling machine for industries is a specialized type of rolling machine that is designed to produce metal parts with extremely high levels of accuracy and consistency. These machines are essential in industries where even the slightest deviation from the specified dimensions can have significant consequences, such as in the aerospace, medical device, and electronics industries. Precision rolling machines for industries incorporate advanced technologies and features to achieve the desired level of precision. One key feature is the use of high-precision rolls that are manufactured with tight tolerances and have a smooth surface finish. These rolls are made from materials with high hardness and wear resistance, ensuring that they maintain their dimensional accuracy over long periods of use. Another important aspect of precision rolling machines is the integration of precise control systems. These systems, often based on CNC technology, allow for accurate control over the rolling process parameters, such as roll speed, pressure, and gap width. The CNC systems can be programmed to execute complex rolling sequences with high repeatability, reducing human error and ensuring consistent quality of the rolled metal parts. Precision rolling machines also utilize advanced measurement and monitoring systems to verify the dimensions and surface quality of the rolled metal in real-time. These systems use sensors and lasers to take precise measurements and provide feedback to the control system, which can make automatic adjustments to the rolling process if necessary. This real-time monitoring helps to prevent defects and ensures that the final product meets the strict quality standards required by the industry. In addition to their precision, precision rolling machines for industries are also designed for high productivity and reliability. They are built with robust structures and high-performance components to withstand the demands of continuous operation in a production environment. Regular maintenance and calibration are essential to maintain the precision and performance of these machines over time. By using a precision rolling machine for industries, manufacturers can produce high-quality metal parts that meet the exact specifications of their customers, improving customer satisfaction and gaining a competitive advantage in the market.